As a civil engineer with over 25+ years of experience in road construction, proper shoulder design and construction are critical for safety, structural support, and drainage. Road shoulders serve many important functions, which I’ll outline in detail below. My name is Steve Axton, and I specialize in efficient pavement techniques and high-performance asphalt mix designs. I am committed to utilizing innovative techniques and materials to construct durable and sustainable paved shoulder roads that withstand various environmental conditions.

Paved shoulder roads are a crucial component of modern transportation infrastructure, providing a safe and durable surface for motorists, cyclists, and pedestrians. As a an experienced professional civil engineer with over 25 years of experience, I’ve witnessed firsthand the importance of well-designed and properly maintained paved shoulder roads in enhancing road safety, reducing maintenance costs, and improving overall traffic flow.

Shoulder Width and Design Standards

In my experience, wider shoulders not only provide more room for disabled vehicles and emergency stopping but also improve sight distances and facilitate easier maintenance operations.

According to the American Association of State Highway and Transportation Officials (AASHTO) guidelines, the recommended paved shoulder width for rural highways ranges from 4 to 8 feet, depending on the design speed and traffic volume. For urban areas, the recommended width is typically 6 to 8 feet.

Two Lane Road With Paved Shoulder

Recommended Paved Shoulder Width

| Road Type | Design Speed | Recommended Paved Shoulder Width |

|---|---|---|

| Rural Highways | ≤ 40 mph | 4 feet |

| 45-50 mph | 6 feet | |

| ≥ 55 mph | 8 feet | |

| Urban Arterials | All Speeds | 6-8 feet |

Creating Professional Looking Paved Shoulders

Paved Shoulders Material Options

Paved shoulders can be constructed using various materials, with asphalt and concrete being the most common choices.

Asphalt Shoulders:

- Composed of a mixture of aggregate and asphalt binder

- Relatively low cost and easy to construct

- Flexible and can better withstand minor cracking or movement

- Typical thickness ranges from 2 to 4 inches

Concrete Shoulders:

- Composed of Portland cement, aggregates, and water

- Higher initial cost but longer service life

- Rigid and can better resist rutting and deformation

- Typical thickness ranges from 6 to 10 inches

Unpaved Shoulders

Unpaved shoulders are often used in rural areas or as a temporary solution before paving. Common materials include:

- Gravel or crushed stone: Provides a stable surface but requires regular maintenance

- Stabilized earth: A mixture of soil and stabilizing agents (e.g., cement, lime) for improved load-bearing capacity

While unpaved shoulders are more cost-effective initially, they require more frequent maintenance and can present safety hazards due to loose material or erosion.

Shoulder Safety Features

A. Rumble Strips

Rumble strips are raised or grooved patterns on the paved shoulder that create vibration and noise when a vehicle’s tires drift off the travel lane. They serve as an effective countermeasure against run-off-road crashes, alerting inattentive or drowsy drivers.

According to the Federal Highway Administration (FHWA), rumble strips can reduce run-off-road crashes by up to 44% on rural two-lane roads and up to 64% on rural freeways.

Rumble Strip Design Tips:

- Width: Typically 16 inches for shoulders

- Depth: 1/2 inch to 5/8 inch for asphalt, 1/2 inch for concrete

- Spacing: Continuous or spaced patterns based on noise concerns

Shoulder Drop-offs

Shoulder drop-offs occur when the height difference between the travel lane and the shoulder exceeds a certain threshold, creating a potential safety hazard. According to the FHWA, drop-offs greater than 3 inches can increase the risk of rollover crashes, particularly for smaller vehicles.

Mitigating shoulder drop-offs involves:

- Regular maintenance to restore proper shoulder elevation

- Installing safety treatments like edge lines, delineators, or safety edges

Shoulder Maintenance and Rehabilitation

Paved Shoulder Maintenance

Common paved shoulder distresses include cracking, rutting, raveling, and edge drop-off. Maintenance practices involve:

- Crack sealing: Filling cracks to prevent water infiltration and further deterioration

- Patching: Repairing localized areas of distress

- Surface treatments: Applying chip seals, slurry seals, or micro-surfacing to extend service life

Unpaved Shoulder Maintenance

Unpaved shoulders require more frequent maintenance due to erosion, rutting, and vegetation growth. Techniques include:

- Grading: Restoring the cross-slope and removing irregularities

- Stabilization: Adding chemical or mechanical stabilizers to improve load-bearing capacity

- Vegetation control: Mowing, herbicide application, or dust control measures

Shoulder Drainage

Proper drainage is crucial for maintaining the structural integrity and longevity of paved shoulder roads. Drainage design considerations include:

- Cross-slope: A 4% cross-slope is recommended for paved shoulders to facilitate drainage

- Ditches and culverts: Providing adequate drainage channels and structures

- Subsurface drainage: Using edge drains or underdrains to remove excess moisture

Paved Shoulder Roads in Rural and Urban Areas

Rural Paved Shoulder Roads

Paved shoulders offer numerous benefits for rural roads, including:

- Improved safety by providing a recovery area for errant vehicles

- Enhanced mobility for disabled vehicles, farm equipment, and bicyclists

- Reduced maintenance costs compared to unpaved shoulders

Design considerations for rural paved shoulder roads involve factors like traffic volume, design speed, and accommodation for larger vehicles (e.g., trucks, agricultural equipment).

Case Study: The Missouri Department of Transportation’s “Paved Shoulders Initiative”

In an effort to improve safety and reduce maintenance costs, the Missouri DOT has been actively adding paved shoulders to rural two-lane highways since the early 2000s. The initiative has resulted in a significant reduction in run-off-road crashes and improved pavement performance, with an estimated savings of $2 million per year in maintenance costs.

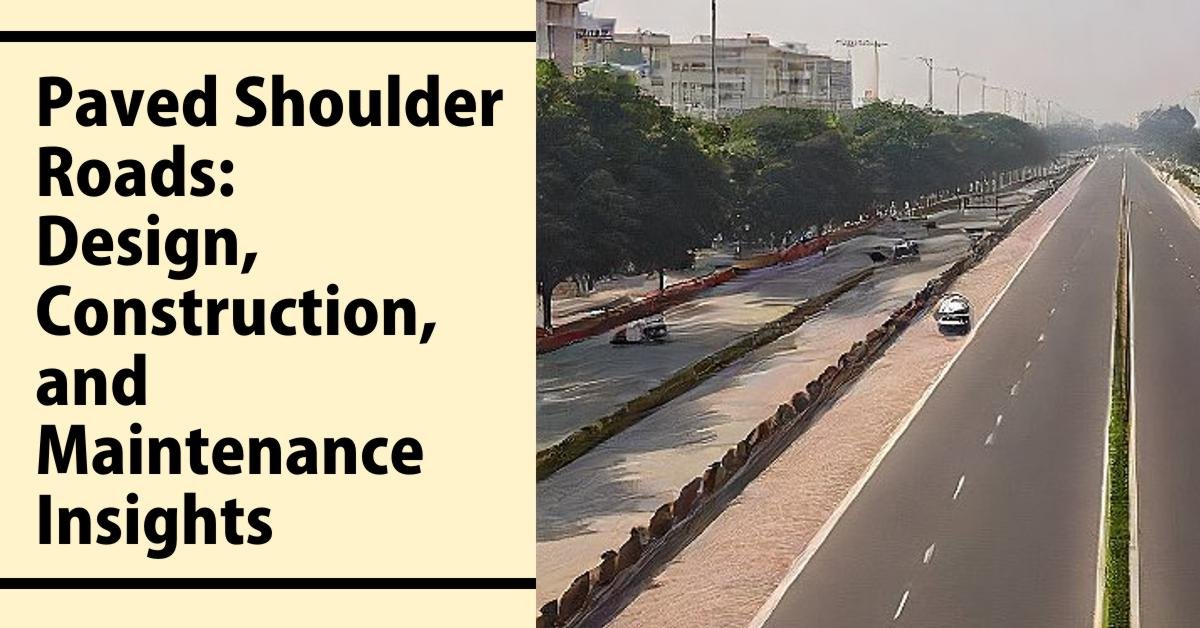

Urban Paved Shoulder Roads

In urban areas, paved shoulders serve multiple purposes, including:

- Providing space for disabled vehicles, bus stops, and turning movements

- Accommodating pedestrians and cyclists in areas without sidewalks or bike lanes

- Facilitating efficient maintenance operations and snow removal

Integrating paved shoulders in urban areas requires careful consideration of factors like parking needs, intersection design, and coordination with other infrastructure elements (e.g., curbs, gutters, sidewalks).

Paved Shoulder Road Safety and Performance

Numerous studies have demonstrated the safety benefits of paved shoulder roads. According to the FHWA, the presence of paved shoulders can reduce run-off-road crashes by up to 35% on rural two-lane roads and up to 49% on rural freeways.

Performance metrics for paved shoulder roads include:

Pavement condition index (PCI):

Evaluate the overall condition and ride quality

Structural capacity:

Measures the ability to withstand traffic loads

Drainage efficiency:

Assesses the effectiveness of drainage systems

Regular monitoring and evaluation of these metrics are essential for timely maintenance and rehabilitation efforts, ensuring the continued safety and performance of paved shoulder roads.

Cost Considerations

While the initial construction costs of paved shoulder roads are higher than unpaved alternatives, the long-term benefits often outweigh the upfront investment. According to a study by the Texas Department of Transportation, the addition of paved shoulders on rural two-lane highways resulted in a benefit-cost ratio of 3.5, primarily due to reduced maintenance costs and improved safety.

Trusted Knowledge Hub

Paved shoulder roads play a vital role in modern transportation infrastructure, enhancing safety, improving mobility, and reducing long-term maintenance costs. By adhering to design standards, implementing proper construction techniques, and adopting effective maintenance strategies, transportation agencies can ensure the longevity and performance of these critical assets.

As a civil engineer with over 25 years of experience, I have seen firsthand the transformative impact of well-designed and properly maintained paved shoulder roads. By prioritizing safety, functionality, and cost-effectiveness, we can create a more reliable and sustainable transportation network for generations to come.

Typical Paved Shoulder Layers Thickness and Material

| Layer | Thickness Range | Material |

|---|---|---|

| Surface Course | 2-4 in | Asphalt or concrete |

| Base Course | 6-8 in | Compacted aggregate |

| Subbase | 6-12 in | Compacted soil |

Shoulder Types

There are several main types of road shoulders:

Unpaved Shoulders

Consists of compacted native soil or aggregate. Used on low-volume rural roads and temporary detours.

Advantages: Low cost, utilizes existing soil.

Disadvantages: Erosion, rough surface, dust and loose material, less load-bearing capacity.

Paved Shoulders

Consists of flexible (asphalt) or rigid (concrete) pavements. Used on higher volume roads for durability.

Advantages: Smoother surface, hold up to weather and traffic loads, better drainage, lower maintenance.

Disadvantages: Higher initial construction cost.

Bicycle Accommodation Paved Shoulders

Bicycles are classified as vehicles in most jurisdictions, and cyclists have the legal right to use the travel lanes on most roadways. However, sharing the road with motor vehicles can be challenging and potentially dangerous for cyclists, especially on high-speed or heavily trafficked routes.

Paved shoulder roads offer a safer and more comfortable alternative for bicycle accommodation. The paved shoulders provide a dedicated space for cyclists to travel, separated from the main travel lanes used by motor vehicles. This separation helps mitigate conflicts between bicycles and vehicles, reducing the risk of collisions and improving overall safety for all road users.

When designing paved shoulder roads with bicycle accommodation in mind, there are several key considerations:

Shoulder Width for Bicycle Accommodation:

Wider shoulders offer more space for cyclists to operate safely. The American Association of State Highway and Transportation Officials (AASHTO) recommends a minimum paved shoulder width of 4 feet to accommodate bicycles, with a preferred width of 5 feet or more on higher-speed roadways.

Surface Quality:

Paved shoulders intended for bicycle use should have a smooth, well-maintained surface free of cracks, potholes, or debris that could cause hazards for cyclists. Regular maintenance and repair of the shoulder surface is essential.

Drainage and Debris Management:

Proper drainage and regular sweeping or clearing of the paved shoulders help ensure that water, gravel, or other debris does not accumulate and create hazardous conditions for cyclists.

Signage and Markings on Road Shoulders:

Clear signage and pavement markings can help delineate the paved shoulders as designated bicycle routes, increasing awareness and visibility for both motorists and cyclists.

Intersection and Driveway Treatments:

Special attention should be given to intersection and driveway crossings, where conflicts between bicycles and motor vehicles are more likely to occur. Appropriate signage, markings, and design treatments can help mitigate these conflict points.

Contrasting pavement: Paved shoulder roads

As a seasoned civil engineer, I understand the importance of not only functionality but also aesthetics and user experience when it comes to transportation infrastructure. The concept of contrasting pavement on paved shoulder roads is an interesting approach that can serve both practical and visual purposes.

From a design perspective, contrasting pavement involves using a different color or material for the paved shoulder compared to the adjacent travel lanes. This contrast can be achieved through various techniques, such as using colored asphalt, concrete, or specialized surface treatments.

The primary practical benefit of contrasting pavement on paved shoulder roads is increased visibility and delineation between the shoulder and the travel way. This clear visual distinction can help improve safety and awareness for both motorists and non-motorized users, such as bicyclists or pedestrians.

For motorists, the contrasting pavement serves as a visual cue that reinforces the separation between the travel lanes and the shoulder area. This can be particularly useful in low-light conditions or during inclement weather, when the shoulder may be less visible.

Additionally, contrasting pavement can enhance the visibility of certain roadway features or treatments, such as rumble strips or safety edges, further improving safety and alerting drivers when they are approaching or encroaching on the shoulder area.

From an aesthetic standpoint, contrasting pavement can be used as a design element to create a visually appealing and cohesive roadway environment. Carefully selected colors or materials can complement the surrounding landscape or urban setting, contributing to a more attractive and inviting experience for road users.

However, it’s important to note that the choice of contrasting pavement materials and colors should be based on thorough evaluations of factors such as durability, skid resistance, and long-term maintenance requirements. Additionally, consistency in application and adherence to established standards and guidelines are crucial to ensure that the contrasting pavement serves its intended purposes effectively and does not introduce any unintended safety hazards.

Edge line rumble strips: Bicycle accommodation on paved shoulders

As a civil engineer, I understand the importance of balancing safety measures with the needs of all road users, including bicyclists. Edge line rumble strips are a proven safety feature that can significantly reduce run-off-road crashes by alerting inattentive drivers when they drift from the travel lane. However, their potential impact on bicyclists using paved shoulders must be carefully considered.

Traditionally, edge-line rumble strips have been designed with a continuous pattern of raised or grooved rumble elements along the edge line separating the travel lane from the paved shoulder. While effective for motor vehicles, these continuous rumble strips can create an uncomfortable and potentially hazardous riding experience for bicyclists traversing the shoulder.

To address this concern, transportation agencies and design professionals have developed bicycle-tolerable edge line rumble strip designs. These alternative designs aim to maintain the safety benefits for motorists while minimizing the impacts on bicyclists using the paved shoulder.

Some examples of bicycle-tolerable edge line rumble strip designs include:

Interrupted or Gapped Patterns:

Instead of a continuous rumble strip, these designs incorporate periodic gaps or interruptions, providing bicyclists with a smooth portion of the shoulder to traverse.

Narrower Rumble Strip Width:

Reducing the width of the rumble strip element itself can help minimize the vibration and discomfort experienced by bicyclists while still providing an audible and tactile warning for motorists.

Offset or Inset Rumble Strips:

By offsetting or inset the rumble strip from the edge line, a portion of the paved shoulder remains smooth and unaffected, allowing bicyclists to ride adjacent to the rumble strip without directly traversing it.

Rumble Stripe Markings:

In this design, the rumble elements are integrated into the edge line pavement marking itself, creating a narrower and more bicycle-friendly rumble experience.

When implementing these bicycle-tolerable edge line rumble strip designs, it’s crucial to ensure that they meet relevant safety standards and guidelines while still providing an adequate level of warning for motorists. Additionally, clear signage and markings can help inform both drivers and bicyclists about the presence and purpose of these modified rumble strip designs.

Composite Shoulders

Use a partial-depth asphalt or concrete pavement over an aggregate or soil base. A cost-effective compromise.

Advantages: Better surface vs. unpaved, lower cost than full-depth pavement.

Disadvantages: Less durable than full paved shoulder.

Curbed Shoulders

Concrete or asphalt curbs are placed at the outer shoulder edge. Prevent vehicle run-off.

Advantages: Improved vehicle recovery, delineates shoulder edge.

Disadvantages: Limits drainage, and hinders emergency stop areas.

Rural vs. Urban Shoulders

Shoulder design often differs between rural and urban/suburban settings based on traffic patterns, costs, aesthetics, and drainage needs.

Rural Road Shoulders

Rural highways and county roads typically have lower traffic volumes and speeds compared to major urban roadways. Large truck traffic may be present for agricultural operations or resource extraction. Roadside vegetation and open drainage ditches are common.

Shoulder surfacing on rural roads usually consists of:

- Unpaved shoulders using compacted native soil or imported aggregates like crushed gravel. Provides basic functions at a very low cost.

- Composite shoulders with a thin surface pavement layer over a compacted base. Offers improved drivability for moderate cost.

Advantages of typical rural shoulders:

- Very low construction and maintenance costs

- Allow vegetation growth alongside roadways

- Provides basic recovery area and drainage functions

Disadvantages:

- Potential shoulder erosion and degradation

- Loose material can cause safety issues

- Poor performance when wet

- Generate dust

Urban/Suburban Road Shoulders

In urban and suburban areas, traffic volumes and speeds are usually much higher compared to rural roads. Aesthetics and stormwater control also become more important. As a result, urban/suburban shoulders are common:

- Paved using asphalt or concrete for a durable, all-weather surface

- Curbed with curb and gutter drainage systems along the outer shoulder edge

Advantages of typical urban/suburban shoulders:

- Paved surfaces provide great drivability

- Withstand weather effects and traffic loads

- Curbs improve drainage and safety control

Disadvantages:

- Substantially higher construction and maintenance costs

- Curbs can hinder maintenance activities

Typical Shoulder Types – Rural vs Urban

| Rural | Urban/Suburban | |

|---|---|---|

| Unpaved | Frequent | Rare |

| Paved | Less common | Typical |

| Composite | Common | Sometimes |

| Curbed | Rare | Typical |

Shoulder Widths

Recommended shoulder widths vary by road classification, traffic volumes, vehicle mix, and location. Some general guidelines:

- High-volume highways: 10-12 ft paved shoulders

- Major arterial roads: 8-10 ft paved shoulders

- Minor arterial/collector roads: 4-8 ft paved shoulders

- Local roads: 2-4 ft unpaved shoulders

- Curbed urban areas: 4-8 ft paved inside curb

Typical Shoulder Widths By Road Type

| Road Type | Shoulder Width Range |

|---|---|

| Highways | 10-12 ft |

| Major Arterials | 8-10 ft |

| Minor Arterials | 4-8 ft |

| Rural Roads | 2-4 ft |

| Urban Curbed Streets | 4-6 ft |

Wider shoulders of 10-12 ft are advisable where significant truck traffic utilizes the road, for safety recovery, and bike/pedestrian space. Insufficient shoulder width leads to reduced safety and shortened pavement life as traffic encroaches on unpaved areas.

Shoulder Cross-Slope

The cross-slope or transverse slope directs stormwater drainage along and away from the roadway. Typical shoulder cross-slopes are 6-12% sloped away from the traveled way. Flatter 4% slopes may be used on curbed shoulders. Steeper slopes over 12% can lead to shoulder erosion. Cross-slopes should be kept as flat as possible to allow errant vehicles to recover safely.

Recommended Cross-Slopes By Shoulder Type

| Shoulder Type | Typical Cross-Slope Range |

|---|---|

| Flexible – High Type | 6-10% |

| Flexible – Low Type | 8-12% |

| Concrete Pavement | 8-12% |

| Curbed Urban | 2-4% |

Shoulder Materials

Shoulder surface materials need to support vehicles when required while promoting drainage. Typical flexible shoulder materials include:

- Asphalt concrete: Durable all-weather pavement. Used for paved shoulders.

- Aggregate: Various crushed stone mixes. Lower cost, moderate durability.

- Compacted soil: Native earthen materials. For lightly used unpaved shoulders.

Rigid concrete shoulders are also used, especially in urban areas. Some common materials include:

- Concrete: Durable rigid pavement. Allows various surface textures.

- Concrete pavers: Interlocking pavers provide a solid surface but are more permeable.

- Gravel: Loose unbound gravel or stone. Requires retention at the edge.

The following table compares the key properties of common shoulder materials:

| Material | Relative Cost | Durability | Drainage Ability | Ease of Install |

|---|---|---|---|---|

| Asphalt Concrete | Higher | Excellent | Moderate | Moderate |

| Concrete | Higher | Excellent | Low | Moderate |

| Aggregate | Low | Fair | Good | Easy |

| Compacted Soil | Lowest | Poor | Moderate | Easy |

| Gravel | Low | Poor | Excellent | Easy |

The right choice balances durability, drainage, cost, and ease of construction. For example, a busy highway calls for durable asphalt or concrete, while a rural road can utilize aggregate or gravel.

Construction and Maintenance

Proper shoulder construction includes:

- Evaluating subgrade strength – improve if needed

- Install any edge drains for subsurface drainage

- Place and compact select fill material in lifts

- Construct shoulder surface course (pavement, aggregate, etc.)

- Confirm proper grading/cross slope for drainage

Maintenance practices include:

- Inspect periodically for settlement, erosion, or edge drop-off

- Patch distressed areas using appropriate materials

- Maintain drainage components (drains, ditches, curbs)

- Address erosion with stabilization or additional surfacing

- Re-grade shoulders and clean drainage structures when needed

With good construction and timely maintenance, road shoulders will serve their vital functions for many years. Quality shoulders improve safety, extend pavement life, and provide space for the many activities that occur alongside roadways. Road shoulder design should be tailored to match the surrounding environment and roadway needs. Rural contexts may utilize more cost-effective unpaved options, while urban areas require enhanced pavements and drainage curbs.

What is road shouldering?

Road shouldering involves the design, construction, and maintenance of the shoulder – the portion of roadway contiguous with the traveled lane that provides lateral support, safety recovery, drainage, and a workspace off the traveled way.

What is the purpose of road shoulders?

Key purposes are providing structural support, increasing safety, facilitating drainage, and accommodating stopped vehicles, cyclists, pedestrians, and maintenance activities off the main roadway.

What is considered the shoulder of the road?

The shoulder consists of the width of the roadway directly adjacent to the traffic lane. It may consist of pavement, aggregate, compacted soil or turf. Curbs often delineate the shoulder edge.

What is the importance of road shoulders?

Proper shoulders reduce traffic encroachment onto unpaved areas, allowing better drainage and preventing edge drop-off. They provide an emergency recovery zone and accommodate various roadside activities away from traffic.

What are road shoulders used for?

Typical shoulder uses include an emergency stop/breakdown area, bike lanes, mail delivery or garbage pickup access, maintenance vehicle operating space, and temporary extra capacity when needed.

Can I put rocks along road shoulders?

Yes, various types of crushed aggregate rock make excellent low-cost shoulder surfacing. Careful grading and compaction is needed to create a stable surface.

Crushed rock aggregate provides a good option for constructing low-cost and durable unpaved road shoulders.

Benefits of Rock Aggregate Shoulders

There are several benefits to using rock aggregate on road shoulders:

- Low Cost – Crushed stone materials are abundant and inexpensive in most regions. Significant savings over asphalt or concrete.

- Good Drainage – The voids between aggregate particles allow water drainage off the roadbed, preventing moisture damage.

- Traction – Angular, interlocked aggregate provides better wet-weather traction than soil or gravel.

- Durability – Hard, strong rocks resist degradation from traffic and the elements are better than Earth.

- Easy to Maintain – Aggregate shoulders can be re-graded and filled easily as needed. Reclaimed material can be reused.

- Reduced Dust – Rock particles tend to stay in place compared to dust from soil or gravel shoulders.

Overall, a properly constructed crushed stone shoulder provides good functionality at low initial and lifecycle costs.

Considerations for Aggregate Shoulders

Some best practices for successful aggregate shoulders include:

- Use well-graded angular crushed rock for stability. Avoid rounded stones.

- Compact in thin layers to 6-8 inches thick to prevent rutting.

- Sloped for adequate drainage, but not so steep as to cause erosion.

- Extend the rock layer over a geotextile fabric for separation from the subgrade.

- Maintain shoulder edge to prevent drop-off and loss of material.

- Inspect regularly and refill any eroded or depressed areas as needed.

Do bridges have shoulders like roads?

Yes, bridge shoulders provide the same benefits as road shoulders. On bridges with lower traffic, shoulders may be narrower than the approaching roadway.

Do all public roads have shoulders?

Many major public roads have paved shoulders, but some rural roads may have only minimal aggregate or turf shoulders depending on traffic volumes and costs. Urban curbed streets typically lack continuous shoulders.

What is a paved shoulder road In India?

As a civil engineer with over 25 years of experience, I define a paved shoulder road as a roadway that features a paved surface extending beyond the travel lanes, providing additional space for vehicles to pull over, accommodate pedestrians and cyclists, and facilitate maintenance operations.

Why are paved shoulder roads important?

Paved shoulder roads are crucial for several reasons, including improved safety, enhanced mobility, and reduced long-term maintenance costs. They offer a stable recovery area for errant vehicles, accommodate disabled vehicles and non-motorized traffic, and require less frequent maintenance compared to unpaved shoulders.

How wide should paved shoulders be?

The recommended width of paved shoulders varies depending on factors like design speed, traffic volume, and the presence of non-motorized traffic. Generally, wider shoulders are recommended for higher-speed roads and those with significant pedestrian or cyclist activity.

What are the common materials used for paved shoulders?

The two most common materials used for paved shoulders are asphalt and concrete. Asphalt shoulders are more cost-effective but may require more frequent maintenance, while concrete shoulders have a higher initial cost but offer a longer service life and better resistance to rutting and deformation.

How do paved shoulders benefit rural roads?

On rural roads, paved shoulders offer several benefits, including improved safety by providing a recovery area for errant vehicles, better accommodation for larger vehicles like farm equipment and trucks, enhanced mobility for bicyclists and pedestrians, and reduced maintenance costs compared to unpaved shoulders.

What role do paved shoulders play in urban areas?

In urban areas, paved shoulders serve multiple purposes, such as providing space for disabled vehicles to pull over without obstructing traffic, accommodating bus stops and turning movements, offering a space for pedestrians and cyclists where sidewalks or bike lanes are absent, and facilitating efficient maintenance operations like snow removal.

What are some common paved shoulder distresses?

Common distresses on paved shoulders include cracking, rutting, raveling, and edge drop-offs. Regular maintenance is crucial to address these issues and prevent further deterioration.

How important is proper drainage for paved shoulder roads?

Proper drainage is essential for maintaining the structural integrity and longevity of paved shoulder roads. Adequate cross-slopes, ditches, culverts, and subsurface drainage systems help remove excess moisture, preventing premature deterioration and extending the service life of the pavement.

What are some safety features used on paved shoulder roads?

Two common safety features used on paved shoulder roads are rumble strips, which alert inattentive drivers when they drift off the travel lane, and safety edges, which allow vehicles to re-mount the shoulder more easily if they drift off, reducing the risk of rollovers.

How do paved shoulders impact maintenance costs?

Paved shoulders generally result in lower long-term maintenance costs compared to unpaved shoulders. While the initial construction cost is higher, paved shoulders require less frequent maintenance and have a longer service life, ultimately offsetting the upfront investment through reduced ongoing costs.

Can paved shoulders be used for temporary traffic control?

Yes, paved shoulders are often used for temporary traffic control during construction or maintenance operations on the travel lanes. By shifting traffic onto the paved shoulder, work zones can be established while still maintaining a reasonable level of mobility and safety for motorists.

What design considerations are important for urban paved shoulders?

When incorporating paved shoulders into urban areas, designers must consider factors such as parking needs, intersection design, coordination with other infrastructure elements (curbs, gutters, sidewalks), and accommodation for pedestrians, cyclists, and public transit.

How can agencies assess paved shoulder road performance?

Agencies can assess the performance and condition of paved shoulder roads through various metrics, including pavement condition index (PCI) to evaluate ride quality and overall condition, structural capacity testing to measure the ability to withstand traffic loads, and drainage efficiency assessments to ensure proper water removal.

What are some emerging trends in paved shoulder road design?

Some emerging trends and innovations in paved shoulder road design and construction include the use of recycled materials like recycled asphalt pavement (RAP) or recycled concrete aggregate (RCA), the incorporation of warm-mix asphalt technologies, the use of innovative surface treatments like high-friction surface courses, and the integration of intelligent transportation systems (ITS) and connected vehicle technologies.

What are the benefits of paved shoulders for pedestrians and cyclists?

For pedestrians and cyclists, paved shoulders offer a safe and stable surface to travel on, particularly in areas without dedicated facilities like sidewalks or bike lanes. This improves mobility and safety for non-motorized traffic.

How do paved shoulders improve road safety?

Paved shoulders improve road safety in several ways, including providing a stable recovery area for errant vehicles, offering a space for disabled vehicles to pull over without obstructing traffic, and allowing for the installation of safety features like rumble strips and safety edges.

What factors influence the choice between asphalt and concrete shoulders?

The choice between asphalt and concrete shoulders depends on factors such as initial construction costs, expected traffic loads, desired service life, and local availability of materials and contractors. Concrete shoulders generally have a higher upfront cost but offer better long-term performance.

How can paved shoulders be integrated with other urban infrastructure?

When integrating paved shoulders in urban areas, it’s crucial to coordinate with other infrastructure elements like curbs, gutters, sidewalks, and utilities. Careful planning is required to ensure seamless integration and efficient multimodal mobility.

What are the environmental considerations for paved shoulder roads?

Environmental considerations for paved shoulder roads include the use of recycled or sustainable materials, minimizing disruption to surrounding ecosystems during construction, and implementing effective stormwater management and erosion control measures.

About the Author

I, Steve Axton am a licensed civil engineer and construction specialist with over 25 years of experience in roadway design, pavement materials, and project management. I have extensive experience in designing and implementing paved shoulder roads, ensuring optimal safety and efficiency for vehicular traffic.

There is no mention of how high or low shoulders should be allowed along the edge of the pavement. This would be appreciated.

Sure I will add the same. (Added)