Asphalt is the most commonly used paving material for everything from driveways and parking lots to city streets and highways. With over 94% of paved roads in the U.S. surfaced with asphalt, its popularity is undisputed.

But what makes asphalt such a preferred paving choice?

What types are available and what factors should you consider for your paving project?

This comprehensive guide on asphalt paving will cover everything you need to know, from its benefits and composition to planning, design, equipment, and construction best practices. Let’s start uncovering the world of asphalt paving.

Why Choose Asphalt Paving?

Asphalt offers numerous advantages that have made it the paving material of choice for decades. Here are some of the key benefits of asphalt paving:

Durability and Longevity

When properly installed by an experienced paving contractor, an asphalt surface can last anywhere from 15 to 20 years. With preventative maintenance like timely seal coating and crack filling, its lifespan can be extended to over 25 years. The durability of asphalt makes it a sound long-term investment.

Strength and Stability

Asphalt pavements can withstand heavy loads, high traffic volumes, and extreme weather fluctuations, making them ideal even for major highways. The stone aggregates bound with asphalt cement create a tough, stable surface.

Smoothness and Drivability

The flexibility and composition of asphalt allow for an incredibly smooth driving surface that stays quiet, safe, and comfortable for many years. The smoothness also reduces wear and tear on vehicles.

Cost-Effectiveness

Asphalt consistently provides the most economical surfacing solution in terms of both installation and life cycle costs. Factors like local availability of materials and ease of construction further add to its cost-efficiency.

Low Maintenance

Other than periodic seal coating, crack filling, and patching, asphalt surfaces require minimal routine maintenance compared to other pavement types. The simplicity of upkeep is a major plus.

Customization and Versatility

With different aggregate gradations and asphalt mixes available, asphalt can be easily customized to meet specific needs – from high-traffic highways to porous parking lots. The versatility of asphalt makes it suitable for virtually any paving application.

Sustainable and Recyclable

Asphalt has a recycling rate of over 99%. Old asphalt is milled and incorporated into new pavement, reducing landfill waste. The recyclability and other eco-friendly qualities make asphalt a sustainability leader.

With this winning combination of advantages, it is easy to see why asphalt reigns supreme when it comes to durable, high-performing, and cost-effective paving.

Here are some statistics, tables, and key facts related to asphalt paving that could be included in a blog post on this topic:

Key Facts about Asphalt Paving

- There are over 2 million miles of paved roads in the United States.

- 94% of paved roads in the U.S. are surfaced with asphalt.

- Around 500-600 million tons of asphalt is produced in the U.S. annually.

- Typical asphalt thickness for highways is around 4 inches. Parking lots usually require 2-3 inches.

- The lifespan of a properly constructed asphalt pavement is 15-20 years.

- The recycling rate for old asphalt is over 99%. It is 100% recyclable.

Asphalt Paving Statistics

Asphalt Pavement Usage in U.S.

| Surface Type | % Share |

|---|---|

| Asphalt | 94% |

| Concrete | 6% |

New Asphalt Pavement Laid Annually

| Paving Type | Lane Miles |

|---|---|

| Highways & Streets | 100,000 |

| Parking Lots | 150,000 |

| Driveways | Over 1 million |

Asphalt Overlay Thickness by Usage

| Location | Thickness |

|---|---|

| Highways | 2-4 inches |

| City Streets | 1.5-3 inches |

| Parking Lots | 1-2 inches |

| Driveways | 1-1.5 inches |

Asphalt Pavement Costs

| Paving Type | Cost per Square Yard |

|---|---|

| New Installation | $5-10 |

| Overlay | $2-5 |

| Patching | $10-30 |

| Sealcoating | $0.15-0.40 |

Asphalt Pavement’ Age

Asphalt Paving Composition

To understand what makes asphalt so successful in paving applications, we must first look at what it is made of. Asphalt pavements contain two essential components:

Aggregates

Aggregates refer to the crushed stone, gravel, and sand particles that make up the bulk of an asphalt mix. Based on their size, aggregates are categorized into fine and coarse aggregates. However, it depends on the specific requirements of each asphalt paving service and asphalt paving company.

Fines consist of fine sand and mineral particles that fill the voids between the larger aggregates, contributing to the mix’s stability. Coarse aggregates come in various sizes like 3/8 inch, 3/4 inch, 1 inch, etc., and provide load-bearing strength.

Asphalt Cement

Asphalt cement, also called asphalt binder, is a dark brown to black petroleum-based sticky material that binds the aggregates together into a cohesive asphalt mix. It provides the adhesive quality that holds aggregates in place and gives asphalt its waterproofing ability.

Asphalt cement makes up just 5-7% of the weight of an asphalt mix. But it is this critical binding agent that gives asphalt pavement its renowned durability as a paving material.

Types of Asphalt Mixes

There are different types of asphalt mixes available, each engineered for specific paving applications and conditions. Some key asphalt mix categories include:

Hot Mix Asphalt Pavement

Hot mix asphalt (HMA) refers to any asphalt mix produced and placed at high temperatures around 300-350°F. The high heat allows the asphalt cement to flow easily and coat the aggregates uniformly, creating a smooth and stable finished pavement.

The two main HMA types are dense-graded mixes and open-graded mixes. Dense-graded HMA has higher fine content and is suitable for major roads carrying heavy traffic volumes. Open-graded HMA contains larger crushed aggregates with lower fines and makes for excellent driving surfaces due to its fast drainage and noise reduction.

Warm Mix Asphalt

Warm mix asphalt (WMA) is produced and placed at temperatures roughly 50°F lower than HMA. By reducing the heat requirements, WMA provides environmental and cost benefits. The lower heat helps the asphalt cement bind better to the aggregates as well.

WMA mixes incorporate special waxes or surfactants that allow the asphalt binder to adequately coat aggregates even at lower temperatures. The warm mix is a greener pavement solution that is rapidly gaining prevalence.

Cold Mix Asphalt

Cold mix asphalt gets its name from the fact that it is produced without heating the aggregates, generally at ambient temperatures. The asphalt binder used in cold mix contains emulsified asphalts and additives that help with binding.

Cold mixes are primarily used for patching potholes and repairs as they remain workable even in cold weather. Their usage for full-fledged paving applications is limited.

Porous Asphalt

Porous asphalt contains large aggregates and highly connected air void content, allowing water to drain through it. The water then infiltrates the underlying porous gravel base, eventually replenishing groundwater. Porous asphalt is thus an eco-friendly solution for stormwater management.

Porous pavements are ideal for parking lots, driveways, and low-volume roads. They help recharge groundwater reserves and reduce stormwater runoff. Their noise-reducing quality is an added benefit.

Choosing the right asphalt mix based on traffic, climate, budget, and specific project requirements is crucial for achieving optimal pavement performance. Consult a professional paving contractor to select the ideal mix.

Asphalt Pavement Distresses

To make informed decisions about asphalt maintenance and repairs, it is important to recognize different forms of pavement distress and their causes:

Cracks and Repair

Cracks are among the most common asphalt defects. Types like alligator, block, edge, and longitudinal/transverse cracks have varied causes but ultimately stem from pavement aging. Timely sealing prevents further deterioration.

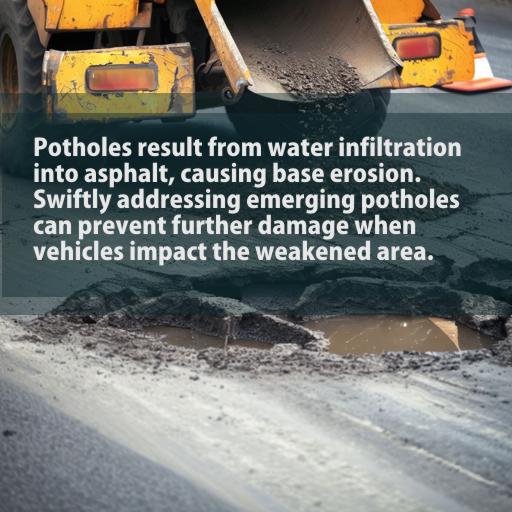

Potholes and seal coating

Potholes form when water seeps into asphalt and erodes the base. Vehicles striking the weakened spot break the surface. Swift patching of emerging potholes can prevent extensive damage.

Rutting

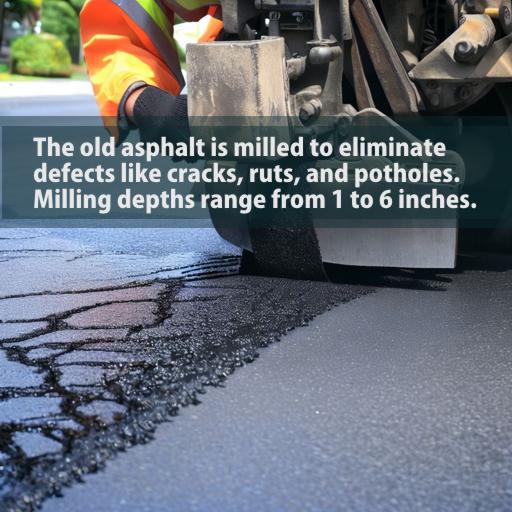

Ruts are depressions in asphalt wheel paths caused by insufficient pavement thickness or poor compaction. Ruts trap water and accelerate deterioration. Milling and overlay may be needed based on severity.

Raveling

This refers to the dislodgement of aggregate particles from the asphalt surface due to aging, poor construction, or insufficient binder. Applying a new pavement coating helps protect against raveling damage.

Shoving

Shoving results from traffic pushing the asphalt longitudinally, causing bumps and dips. It indicates an unstable mix or weakened base. Shoved areas may need patching or complete replacement.

Drainage Failure

Inadequate slopes that prevent water drainage lead to moisture damage, cracks, and potholes. Re-grading and re-paving ensure proper drainage and prevent premature failure.

Detecting distress early and performing timely repairs minimizes the extent and cost of rehabilitating damaged pavements.

Asphalt Paving Equipment

Constructing quality asphalt pavements requires specialized equipment operated by experienced crews. Here is an overview of key equipment used in asphalt paving:

Asphalt Mixing Plants

Asphalt plants blend aggregates and asphalt cement into hot mix asphalt for transport to paving sites. Plants come in portable or stationary designs to suit different production needs.

Haul Trucks in Paving Services

Trucks transport hot asphalt mix from plants to job sites, ensuring it is workable when paving begins. Keeping mix temperatures above 280°F during transport is crucial. Insulated truck beds prevent heat loss.

Asphalt Pavers

Asphalt pavers are specialized machines that place and spread mix evenly across widths up to 16 feet at a time. Modern pavers provide smoothness, speed, and efficiency in pavement construction.

Asphalt Compactors

Compactors provide the required density and smoothness to asphalt pavements after placement by rollers pressing down the hot mix. Steel drum rollers, pneumatic rollers, and vibratory rollers are common types.

Milling Machines

Also called cold planers, milling machines remove worn asphalt layers by “chewing” them up with their rotary cutting drums prior to overlay. This provides a textured surface for bonding the new layer.

Material Transfer Vehicles

Material transfer vehicles (MTVs) shuttle mix from haul trucks to pavers and help maintain paver speed for superior mat quality on large projects. Their usage improves overall paving efficiency.

Investing in modern, well-maintained equipment operated by trained technicians is imperative for asphalt paving contractors to deliver quality results consistently.

Asphalt Paving Process

The asphalt paving process consists of distinct steps that require meticulous execution:

Site Evaluation

Evaluating existing site conditions even before design allows the collection of key data like soil tests, drainage, traffic patterns, measurements, and records of previous failures. This informs decisions on repair techniques, mix design, etc.

Mix Design

The right asphalt mix is formulated based on testing to meet specific climate and traffic needs. The design process determines the exact blend of binder and aggregates that will provide the required pavement performance as per paving needs. The quality asphalt paving services provide commercial paving services for parking lot paving.

Surface Preparation

For overlays, the existing surface is milled down to remove distressed areas and provide a smooth, uniform surface for paving. Cracks are sealed, patches applied, and the surface cleaned following milling. Sometimes concrete and asphalt mixture is used to create state-of-the-art roadway payments to reduce payment maintenance in the future.

Tack Coat Application

A thin tack coat is sprayed over the prepared surface just before paving begins. The tack coat ensures strong adhesion between the new overlay and the existing layer beneath.

Pavement Placement

The hot mix asphalt is transported from plants and placed by pavers at the required thickness, width, and slope according to the paving plan. Material transfer vehicles feed mix to pavers on large projects.

Compaction

Compactors immediately compact the freshly placed mix to the desired density before it cools. Steel rollers, sometimes followed by pneumatic rollers, are used based on mix type and thicknesses.

Quality Control

Technicians constantly monitor factors like temperature, smoothness, and compaction density to ensure standards are met. Any deficiencies can be addressed in real-time during paving. The high-quality services use proper equipment to ensure customer satisfaction.

With its numerous intricacies, asphalt paving must always be executed by experienced contractors using proper techniques for lasting results.

Asphalt Overlays and Reconstruction

There are two main approaches for repairing aged and deteriorated asphalt – overlays and full reconstruction:

Asphalt Overlays

Asphalt overlays involve placing a new layer of asphalt over the existing pavement surface after preparing it by repairs and milling. Thickness ranges from 1.5 to 3 inches for parking lots and driveways. Highways may require up to 8-inch overlays.

Overlays restore ride quality, waterproof surface, increase load capacity, and deliver a brand new-looking surface at a fraction of reconstruction costs. They extend the life of pavements by 10-15 years.

Full-Depth Asphalt Reconstruction

When asphalt deterioration is too extensive for simple overlays, full-depth reconstruction is needed. It entails the complete removal and replacement of existing asphalt layers along with the base below.

Full reconstruction has higher upfront costs but delivers a restored “like-new” pavement designed to last 20-30 years with proper maintenance. It is ideal when major upgrades are also needed.

Consider factors like budget, extent of damage, future traffic, overall plans for the property, and initial construction quality when deciding between overlays and reconstruction.

Porous Asphalt Paving

Porous asphalt is a unique paving solution that allows stormwater to drain through it, reducing runoff. Here is an overview:

How Does It Work?

Porous asphalt contains minimal fine aggregates, leaving interconnected voids that allow water to infiltrate the pavement’s porous base below, eventually replenishing groundwater.

Applications

Porous asphalt is ideal for parking areas, trails, driveways, and low-volume roads. It provides environmental and safety benefits.

Advantages

Porous asphalt reduces stormwater runoff, minimizes flood risks, improves skid resistance, replenishes aquifers, and lowers heat island effects. It can earn projects LEED points.

Considerations

Porous asphalt requires gentle sweeping instead of plowing for snow removal. Vacuuming is needed periodically to prevent clogging of pores and ensure the system functions efficiently.

Structural Design

A porous asphalt system requires a uniformly graded crushed stone base between the porous layer and the soil below for temporary water storage and infiltration.

With its unique stormwater management capabilities, porous asphalt is an increasingly popular green pavement solution.

Asphalt Paving Best Practices

Adhering to industry best practices is essential for asphalt paving success. Here are some top tips:

- Choose an experienced paving contractor with modern equipment and trained staff. Verify project references and certifications.

- Ensure the base is constructed properly with adequate compaction, drainage slopes, and stability to support loads.

- Use a mix design optimized for local conditions. Establish quality control testing procedures.

- Follow specifications for tack coat application prior to paving. Do not allow traffic on tacked surfaces.

- Maintain mix temperatures during transport and track tonnage placed. Record surface temperature during paving.

- Use string lines on mat edges to guide pavers and ensure straight pavement edges.

- Compact mix thoroughly and immediately while still hot. Meet density specifications.

- Inspect finished pavement for issues like improper thickness, low density, smoothness, or mix problems.

- Wash equipment and transport vehicles regularly to prevent asphalt build-up and mix contamination.

Adhering to best practices minimizes risks during construction and ensures satisfactory results.

Asphalt Paving Maintenance

Proper asphalt maintenance preserves pavement quality, extends lifespan, and delays major repairs. Recommended maintenance activities include:

Crack Sealing

Sealing cracks periodically prevents water intrusion into the base, which causes potholes and deterioration. Cracks wider than 1⁄4 inch should be filled.

Sealcoating

Applying a protective seal coat layer every 2 to 4 years rejuvenates weathered asphalt, fills hairline cracks, and prevents raveling and oxidation damage.

Patching

Promptly patching distressed areas and potholes prevents further loosening of the base. Permanent patches provide longer service life than temporary ones.

Line Striping

Restriping improves the visibility of road markings that fade over time. Reflective paints enhance nighttime visibility.

Drainage Upkeep

Ensuring drains, shoulders, curbs, and slopes that facilitate runoff remain functional is imperative for pavement health.

Sweeping

Regular sweeping prevents debris accumulation that can clog pores on porous pavements. It also enhances overall pavement appearance.

Snow Removal

Plowing and de-icing timely ensures safety. Porous asphalt requires gentler sweeping instead of plowing which can damage the surface.

Regular asphalt care provides substantial long-term savings compared to allowing widespread deterioration that necessitates deep-layer repairs or full reconstruction.

Asphalt Paving Specifications

Clear specifications are crucial for successful asphalt paving projects. They provide measurable standards for contractors to follow during construction and allow owners to assess quality. Typical specifications cover:

Materials

Asphalt type and grade, aggregate grades, and mix design criteria based on traffic and climate.

Base Preparation

Requirements for excavation depth, backfill material, compaction, and density/stability of the base.

Overlay Type

Milling depth, leveling course details, minimum overlay thickness, tack coat application rate, mix temperature, and density targets.

Testing

Test methods, frequency, and acceptance criteria for factors like mix volumetrics, smoothness, and in-place density.

Construction

Environmental conditions, joint details, production rates, placement processes, and protection of completed work like restricting traffic until cooling.

Quality Control

Inspection access, sampling, contractor testing, rectification of rejected work, traffic control, and project documentation required.

Measurement and Payment

Method of final quantity measurement and payment terms.

Well-defined specifications avoid ambiguity and ensure optimal pavement construction, performance, maintenance, and life cycle costs. They benefit both contractors and owners.

Innovations in Asphalt Pavement

The asphalt industry continually adopts innovations to enhance pavement sustainability, quality, and performance. Some emerging trends include:

Warm Mix Asphalt

Production temperatures are lowered significantly compared to hot mix asphalt, resulting in lower emissions and energy consumption. Warm mix usage is increasing steadily.

Recycled Asphalt

Reclaimed asphalt pavement (RAP) and recycled asphalt shingles (RAS) are being used in larger percentages in new mixes to reduce raw material usage.

Extended Binder Technology

Special agents are added to asphalt binder to increase durability and resistance to cracking, rutting, and moisture damage.

Pavement Recycling

Cold in-place recycling rejuvenates and reuses existing pavement material in situ using special equipment. This eliminates the transport and disposal costs of old asphalt.

Warm Mix Asphalt Additives

Organic additives made from agricultural by-products are emerging as more sustainable warm mix technologies with lower emissions.

Asphalt Mix Perpetuation

New processes can perpetuate optimized asphalt mixes for future use. This avoids reformulation and testing every time a mix is needed.

Pavement Preservation

A proactive approach to preventive maintenance and timely minor repairs is being emphasized to extend pavement life at lower costs.

Pavement Smoothness

Precision construction equipment and processes ensure smoothness standards are met, resulting in improved safety and ride quality.

Leveraging Cold In-Place Recycling to Rejuvenate Crucial Interstate Lanes

As lead project engineer, I faced immense pressure ensuring the rehabilitation of a heavily trafficked 8-mile corridor of degraded interstate pavement made the tightest possible delivery timeline to minimize shutdown impacts. Yet top quality and long-term durability could not be sacrificed either on this backbone goods movement artery.

My proposed solution: conduct targeted cold in-place asphalt recycling coupling intelligent partial reclamation with virgin surface overlay upgrades. This balanced approach allowed for reusing existing sound material assets while revitalizing wear susceptibility and updating functional tolerances.

Once commissioned, my construction team used special milling machines to remove the top 4 inches of distressed pavement across all non-structural cracks areas into mobile processing units. The reclaimed material was precision blended with customized rejuvenating agents I designed responding to petrographic lab testing of particle distribution and binder content within the existing bitumen mix samples.

Augmenting particle separation and reactivating aged binders with the engineered emulsion cocktails returned structural integrity to the recycled mats based on cohesion testing. We supplemented the rehabilitated pavement with precisely graded 1.5-inch hot mix asphalt overlays boosting ride quality where wheel path depressions existed thanks to 3D profilometry identifying areas needing augmented repair and level-up support.

The project finished over 60 days ahead of traditional removal and replacement timelines while reducing landfill waste disposal demands by 185,000 tons. Incorporating cold in-place recycling technology saved taxpayers over $7.3 million in material import fees and traffic control resource allocations. Six years later, the rehabilitated highway maintains exceptional pavement condition index smoothness ratings—validating my steadfast support of properly engineered recycling solutions for aging infrastructure.

Data Integration

Integrating technologies like 3D project modeling, infrared imaging for distress detection, and intelligent compaction provides real-time data for quality and performance enhancement.

Autonomous Construction

Automated and remote-controlled equipment removes workers from high-risk areas on large highway projects and improves operational efficiency.

Sustainable Materials

Increased use of recycled content, alternative binders from bio-materials, and construction methods with lower carbon emissions promote sustainability.

Pavement Management Systems

Advanced modeling programs effectively optimize maintenance, repair, and rehabilitation activities based on accurate prediction of pavement degradation.

Continued innovation and adoption of cutting-edge solutions will elevate asphalt paving quality, durability, efficiency, and sustainability to new heights.

How hot is asphalt when paving?

Asphalt is typically heated to between 300-350 degrees Fahrenheit during the mixing process at the plant. It is then transported in trucks to the paving site and must maintain temperatures over 280 degrees F during paving to remain workable and pliable. The hot mix asphalt is spread and compacted before it cools down and hardens. Proper temperature is crucial for successful asphalt paving.

What’s the difference between asphalt and blacktop?

Asphalt and blacktop refer to the same material. Blacktop is a colloquial term used to describe asphalt pavement due to its dark black color after installation. The terms asphalt and blacktop can be used interchangeably.

Is asphalt the same as concrete?

Asphalt and concrete are two different paving materials. Asphalt consists of liquid asphalt binder and stone aggregates mixed together. Concrete uses a mixture of cement, sand, gravel and water. Asphalt is more flexible while concrete is rigid. Asphalt needs compaction while concrete cures as a solid. Asphalt is widely used for roads while concrete is preferred for structures.

How long does it take for asphalt to dry?

Freshly laid asphalt begins cooling immediately and is ready for traffic typically within a few hours after paving. However, it continues to cure and fully harden over the next 72 hours. Asphalt achieves its maximum strength over 6-12 months as the binding asphalt cement oxidizes and ages.

Why are roads asphalt instead of concrete?

Asphalt is preferred over concrete for roads due to its smoothness, flexibility, cost efficiency, and speed of installation. Asphalt provides a comfortable ride, adapts to temperature changes, is simple to repair, and needs lower maintenance. Concrete has limited flexibility, is prone to cracking and faults due to ground movement, and is costlier.

What type of asphalt is best for roads?

For high-traffic roads and highways, polymer-modified performance grade (PG) asphalt is considered the best. PG asphalt uses polymers to strengthen the asphalt binder, enhancing durability and resistance to rutting and cracking. The PG grade is selected based on regional temperature characteristics.

What are the benefits of asphalt?

Key benefits of asphalt include its recyclability, smoothness, speed of construction, low noise, cost-efficiency, customizability, all-weather paving ability, sustainability, and low maintenance needs. Asphalt also provides good skid resistance and water drainage.

What are the two layers of asphalt?

The base course and surface course are the two asphalt layers in pavement structure. The base course layer provides strength and load-bearing support. It uses larger aggregate mixes. The surface course is the top visible layer finer mixes to create a smooth, durable riding surface and protect the base course underneath.

How many layers of asphalt are on a road?

Highways typically have four layers – sub-base, base course, binder course, and surface course. City roads usually have three layers – sub-base, base course, and surface course. Driveways and parking lots may have just two layers – base course and surface course over the sub-grade soil.

Is asphalt the same thing as blacktop?

Yes, asphalt and blacktop are the same material. Blacktop is an informal term used to describe asphalt pavement due to its dark black appearance after paving. Asphalt is the proper engineering term used to refer to the black, petroleum-based paving material.

Which is harder asphalt or concrete?

Concrete is harder than asphalt. On the Mohs scale of mineral hardness, asphalt ranks between 0.5 to 1 while concrete ranks from 6 to 7, comparable to granite. This explains concrete’s brittleness. Asphalt’s softness allows flexibility but needs thicker sections for equivalent strength.

Is asphalt concrete or blacktop?

Asphalt is neither concrete nor pure blacktop. Asphalt pavement consists of liquid asphalt binder mixed with crushed stone aggregates. The term blacktop comes from its black appearance and is used interchangeably with asphalt. Concrete uses cement, sand, gravel, and water but no asphalt binder.

How can you tell if it’s concrete or asphalt?

Simple ways to distinguish concrete vs. asphalt: Concrete has visible coarse aggregates while asphalt looks uniformly black. Concrete has visible joints while asphalt has uniform, unbroken surfaces. Concrete turns lighter gray over time while asphalt turns more black. Concrete is rigid while asphalt is slightly flexible.

Is pavement the road or sidewalk?

Pavement refers to any hard, paved surface including roads, sidewalks, driveways, parking lots, runways etc. Both asphalt and concrete surfaces used for these applications qualify as pavement. The term pavement simply means any paved, all-weather surface made using materials like asphalt, concrete, or pavers.

Why is asphalt used for roads instead of concrete?

Asphalt is preferred over concrete for roads due to advantages like smoothness, quietness, cost efficiency, speed of construction, and easy repairability. Asphalt provides the ideal paved surface for roads to sustain traffic loads and different weather conditions. Concrete is more prone to cracking and needs higher maintenance.

Does pavement mean concrete?

No, pavement does not mean only concrete. Pavement refers to any hard, paved surface material including asphalt, concrete or pavers. Roads and sidewalks can be paved using asphalt or concrete. Asphalt pavement is actually more common on roads while concrete is used more for sidewalks and residential driveways.

How many types of asphalt pavement are there?

Major asphalt pavement types include hot mix asphalt, warm mix asphalt, cold mix asphalt, mastic asphalt, porous asphalt, and stone matrix asphalt. They can be further categorized based on production process, aggregate type and sizes, and mix gradation. There can be hundreds of customized asphalt mix designs.

Why is it called a pavement?

The term “pavement” comes from Late Middle English referring to a paved surface or hard flooring. It stems from the Latin “pavimentum” derived from “pavire” meaning to beat or ram down earth or stone. This refers to compacting techniques used historically to create paved streets and floors using materials like stone, brick, tile, or wood blocks.

What is pavement or driveway?

Pavement refers to any paved, all-weather surface made using materials like asphalt, concrete, or pavers. Driveway refers specifically to a paved surface providing access from a public road to a building or structure, typically a residential home. So a driveway signifies a type of pavement with its unique location and purpose.

What is blacktop made of?

Blacktop is an informal term for asphalt pavement. It is called blacktop because of its black color after installation. Blacktop consists mainly of stone aggregates like crushed gravel and sand mixed with asphalt cement as the binder. The asphalt binder gives the mix its black color.

Why do they call asphalt asphalt?

Asphalt derives its name from Late Middle English via French and Latin from Greek “asphaltos”, meaning asphalt, bitumen. The Greeks named it “asphaltos” due to the term “a” meaning “not” and “sphalein” meaning “to draw out”, referring to asphalt’s sticky nature. The word “asphalt” has been widely adopted globally as the generic term for bituminous paving materials.

What are the disadvantages of asphalt?

Disadvantages of asphalt include the potential for rutting and cracking over time, softness susceptible to scuffing, petroleum-based binder concerns, odors during paving, longer curing times vs concrete, costly removal if replacement is needed, and not ideal for harsh winters without proper maintenance.

Why do they put asphalt over concrete?

Asphalt overlay on concrete provides a smooth, quiet, and skid-resistant surface while restoring deteriorated concrete condition at lower costs. Asphalt binder seals cracks fills joints, and waterproofs old concrete surfaces. Asphalt overlay is an economical solution to rehabilitate aging concrete roads and enhance ride quality.

What are the advantages of asphalt?

Major advantages of asphalt include its recyclability, smoothness, quietness, low maintenance needs, skid resistance, fast and easy construction, versatility, all-weather paving ability, sustainability, customizability using various mixes and aggregates, and cost-effectiveness compared to other pavement materials.

What type of asphalt is used on streets?

For city streets, the most common asphalt type used is hot mix asphalt (HMA) with a dense-graded surface course utilizing smaller aggregate sizes. Within HMA, Superpave mixes like stone matrix asphalt provide enhanced performance for heavily trafficked city streets. Warm mix asphalt is also gaining prevalence on streets due to lower production temperatures.

What are the advantages and disadvantages of asphalt?

Advantages include smoothness, quietness, cost efficiency, fast construction, sustainability, custom mixes, all-weather paving, and low maintenance. Disadvantages include potential cracks over time, softness prone to scuffing, petroleum usage concerns, odor during paving, longer curing time than concrete, expensive removal, and issues in extremely cold climates without proper maintenance.

Is asphalt used in concrete?

Asphalt is not typically used in the production of concrete. Asphalt and concrete are two different paving materials. Concrete uses a mixture of cement, sand, gravel, and water. Asphalt binder is added to aggregates like crushed stone and gravel to make asphalt pavement. There are some asphalt-extended concrete products using small amounts of asphalt but conventional concrete does not contain asphalt.

What is asphalt pavement made of?

Asphalt pavement consists mainly of stone aggregates like crushed gravel and sand bound together using asphalt cement. The aggregates account for over 90% by weight while asphalt cement makes up around 5-10%. Asphalt cement is the black, sticky petroleum-based binder that gives asphalt its distinctive appearance and properties.

Is asphalt the same as tar?

Asphalt and tar are two different substances. Tar is a dark brown or black viscous liquid obtained from the destructive distillation of organic substances like wood or coal. Asphalt is a black, sticky petroleum-based binder used for paving. While both are viscous liquids, their contents and applications differ significantly.

How much weight can 2 inches of asphalt hold?

The weight bearing capacity depends on the type of asphalt mix and base layers underneath. Typically, 2 inches of dense-graded asphalt over an 8-inch crushed stone base can handle occasional vehicle loads up to around 2500 lbs per square foot, which is enough for most cars and light trucks. Heavier vehicles need thicker asphalt layers.

Is asphalt the same as blacktop?

Yes, asphalt and blacktop refer to the same paving material. Blacktop is an informal term used to describe asphalt pavement because of its black appearance after installation. Asphalt is the proper engineering term for the mix of aggregates and asphalt cement used for paving applications.

Why do they use asphalt instead of concrete?

Asphalt is used more than concrete for paving due to advantages like smoothness, quietness, flexibility, speed of paving, simple maintenance and repairs, and cost efficiency. Asphalt provides a comfortable driving surface and adapts well to subgrade movements and temperature fluctuations compared to more rigid concrete.

Is it cheaper to concrete or paving?

Overall, asphalt paving costs less compared to concrete paving on a new installation and lifetime cost basis. Asphalt driveways cost $2-$5 per square foot installed versus $4-$8 for concrete driveways. Similarly, asphalt lot paving averages $0.50-$2 per square foot while concrete lot paving runs $2-$6. Asphalt provides significant long-term savings.

Is asphalt the best for a driveway?

Asphalt is considered one of the best driveway paving materials along with concrete and pavers. Advantages like affordability, quick installation, customization, quietness, imprint options, and low maintenance make asphalt an ideal driveway paving solution for many homeowners.

Which is harder cement or asphalt?

Cement is much harder than asphalt. Cement rates between 8 and 9 on the Mohs mineral hardness scale while asphalt ranks from 0.5 to 1, comparable to materials like talc or gypsum. The higher hardness makes cement more brittle. Asphalt’s relative softness provides flexibility but requires thicker sections for equivalent strength.

Is asphalt or concrete easier to walk on?

Asphalt is generally regarded as easier and more comfortable to walk on compared to concrete sidewalks or paths. Asphalt provides a slightly spongy feel while concrete feels rigid and hard. The dark color of asphalt also radiates more heat, keeping it clear of snow/ice longer. Asphalt is also quieter underfoot than concrete.

Which type of pavement is better?

Asphalt and concrete both make excellent pavement materials, each with pros and cons. Key factors for selection include cost, traffic volumes, subgrade conditions, location climate, sustainability needs, priorities for smoothness or quietness, and maintenance considerations. For many paving uses, asphalt provides a better overall value.

Is asphalt more forgiving than concrete?

Yes, asphalt is more forgiving and flexible compared to rigid concrete. Asphalt’s relative softness makes it less prone to cracking and faults from ground movements or freeze-thaw cycles. Asphalt absorbs stresses better and adapts to subgrade imperfections during paving. It is also simpler and cheaper to patch small areas of damaged asphalt compared to concrete.

Is asphalt softer than the sidewalk?

Standard asphalt pavement provides a slightly softer walking surface compared to concrete sidewalks. Asphalt rates 0.5-1 on the Mohs scale while concrete rates from 6-7, closer to granite in hardness. The stone aggregates embedded in concrete make for a rigid, unyielding surface. Asphalt’s dark color also makes it warmer underfoot.

Is sidewalk harder than asphalt?

Yes, sidewalks are typically harder than asphalt pavement since they are usually constructed using concrete. On the Mohs scale, concrete rates from 6-7 in hardness while asphalt ranks from 0.5-1. Concrete’s rigid nature comes from its composite structure of coarse aggregates bound in a cement matrix. Asphalt’s malleability stems from aggregated coated by viscous, flexible asphalt cement.

In summary, asphalt and concrete possess unique qualities that make them suitable for different paving applications. Asphalt’s cost-efficiency, smoothness, quietness, customization, and sustainability advantages make it an ideal choice for roads, driveways, and parking areas. Concrete excels in hardness and structural strength needed for infrastructure like sidewalks and foundations. Understanding the nuances helps select the most appropriate paving material.

Emerging innovations in asphalt paving:

Robotics

Robotic arms and automated guided vehicles are being adopted for tasks like moving and placing mix and controlling compaction equipment. This improves efficiency and consistency.

Paver Screed Control

New screed technologies use vibration, heating, and pressure to optimize smoothness and density during paving for superior ride quality.

Intelligent Compaction

Smart compaction rollers have integrated sensors that provide real-time feedback on applied force and number of passes to achieve the required density with precision.

Remote Quality Control

Mobile apps and cloud-based platforms enable remote monitoring and documentation of key metrics like mix temperature and smoothness, improving quality oversight.

Infrared Repair

Infrared heat is used to partially soften and rework distressed areas of asphalt pavements, providing rapid in-place fixing of damage.

Warm Mix Additives

Organic additives made from agricultural products are emerging as greener warm mix technologies with lower emissions compared to WMA with traditional additives.

3D Project Modeling

Modeling programs integrate mixed requirements and traffic data to predict virtual performance. This facilitates accurate mix designs and structural enhancements.

Carbon Emissions Reduction

The usage of recycled mixes, alternative binders, warm mix technologies, and process efficiencies continue to low carbon footprint.

Advancements and breakthroughs will continue expanding possibilities with asphalt paving solutions that enhance cost, quality, and sustainability.

Commercial Paving

Commercial or “private paving,” involves the art and skillful care needed to surface roads, parking lots, driveways, and pathways that serve businesses, enterprises, or individual property owners. While municipal paving encompasses wider public infrastructure needs, commercial paving focuses on individual business successes while municipal paving addresses broader public infrastructure issues. Here we explore key characteristics defining commercial paving: its purpose, design considerations regulatory landscape longevity as well as how commercial spaces benefit from increased curb appeal and functionality from its implementation.

Choosing the best Paving Contractor

Choosing the best paving contractor is like selecting the perfect puzzle piece. You want a contractor that fits seamlessly into your project, providing the expertise and quality craftsmanship needed to complete the puzzle perfectly.

Commercial Paving vs. Municipal Paving:

When it comes to laying down pavement, there are two main types – Commercial Paving and Municipal Paving. Each has its own set of rules and impacts on our daily lives. In this comparison, we dive into the world of these two types of paving, highlighting their differences in ownership, size, purpose, design, rules, upkeep, and how they affect the public. Whether you’re a property owner looking to improve the look of your property or a city in charge of public infrastructure, it’s important to understand the differences between these two methods of paving so you can make the right decisions.

| Aspect | Commercial Paving | Municipal Paving |

|---|---|---|

| Ownership | Private entities | Local government |

| Scale and Complexity | Varies widely | Large-scale, complex |

| Purpose | Business needs | Public transportation |

| Design Considerations | Aesthetics, curb appeal | Functionality, safety |

| Regulations and Codes | Local regulations | Government standards |

| Longevity and Maintenance | Property owner responsibility | Government-funded upkeep |

| Public Impact | Limited disruption | Widespread impact |

Conclusion

With its unparalleled advantages, proven performance record, innovations, and established best practices, asphalt paving will undoubtedly continue thriving as the paving material of choice for generations to come.

Asphalt’s customizability and versatility cement its role in sustainably building infrastructure to the highest standards even as transportation needs evolve.

Delivered by experienced paving professionals adhering to modern technologies and stringent quality processes, asphalt pavements provide superior value and satisfaction. By following the guidance in this comprehensive asphalt paving guide, you can have confidence that your next paving project will meet your needs successfully in the long run.