As a civil engineer with decades of experience in asphalt materials and specifications, I often get asked about decorative driveway options by homeowners looking to add curb appeal. Stamped asphalt has emerged as an elegant yet affordable paving choice. This guide will explore the benefits of stamped asphalt driveways and help you determine if it’s the right solution for your home.

What is a Stamped Asphalt Driveway?

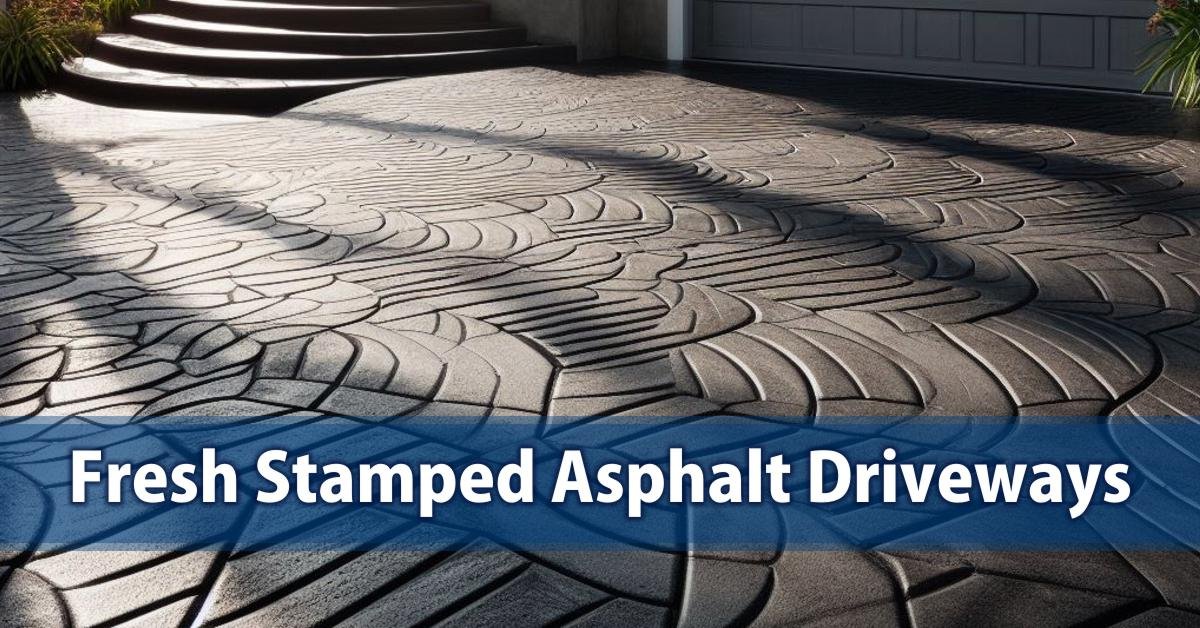

Stamped asphalt driveways are decorative, patterned driveways created by imprinting hot asphalt with a stamping template pressed into the surface by a plate compactor. The stamping tools form textures that mimic materials like brick, cobblestone, slate, limestone, and granite. Stamped asphalt allows you to get the visual appeal of pavers, bricks or stones at a fraction of the cost.

The process starts by installing a traditional asphalt driveway. While the asphalt is still warm and pliable, typically around 300°F, the stamped asphalt contractor uses templates to imprint the desired pattern into the malleable surface.

The result is a uniquely styled driveway with the strength and durability of asphalt combined with the elegant decorative touch of patterns that replicate bricks, cobblestones or pavers.

With so many template styles and patterns to choose from, you can customize your driveway’s appearance. Stamped asphalt provides an affordable way to get the upscale paved look you want while still utilizing reliable asphalt material. The heat used in installation helps seal and set the patterns for long-lasting curb appeal.

Stamped Asphalt Pattern Styles

| Pattern | Description |

|---|---|

| Brick | Replicates the look of classic brick driveways |

| Cobblestone | Mimics rustic, old-world cobblestone streets |

| Slate | Elegant stone-like appearance in shades of grey |

| Limestone | Natural tan and beige tones |

| Granite | Speckled and veined like granite aggregates |

| Custom | Fully customized patterns or logos are available |

Why Choose Stamped Asphalt?

Beyond the decorative curb appeal, what makes stamped asphalt an excellent choice for homeowners?

Durability and Longevity

The inherent flexibility and density of asphalt make it an incredibly durable material. Properly maintained asphalt driveways can last over 20 years even in cold climates. Unlike concrete, asphalt is more flexible and resistant to cracking from ground movement and freeze-thaw cycles. The same durability applies to stamped asphalt patterns. The stamping process helps seal and compact the asphalt, priming it for a long lifespan.

Easy Maintenance

Another benefit of stamped asphalt is easier upkeep compared to stamped concrete. Asphalt requires far less constant maintenance to prevent stains, cracking, and chipping. Refurbishing an existing asphalt driveway with stamping is more feasible than trying to repair stamped concrete. Damaged concrete typically needs full replacement.

Quick Installation

Stamped asphalt can be installed extremely quickly, often in less than 48 hours. After spreading and compacting the asphalt, the stamping process takes just hours more before you can drive on it. Concrete takes substantially longer to cure before use. Pavers are tedious to install and take more time.

Cost Savings

The material cost of asphalt is far less than concrete, bricks, or pavers. Labor is also reduced with the speedy process. Stamping an existing driveway is even more affordable since new asphalt isn’t required. The decorative appearance comes at a fraction of the price of other options.

Customization

Stamped asphalt can be customized with boundless patterns, colors, designs, borders, and more. You can create fully unique designs to suit your home’s style. Concrete stamping limits you to basic stone or brick looks.

Clearly, the advantages of stamped asphalt from installation to maintenance make it an excellent choice for homeowners wanting an elegant, distinctive driveway.

What to Know Before Choosing Stamped Asphalt

Of course, there are a few considerations to weigh before committing to a stamped asphalt driveway:

- Climate – In extreme cold, asphalt can be prone to more cracks and dents needing repair. Usage and seal coating needs may increase.

- Cost – Upfront cost is low, but ongoing maintenance and eventual resurfacing add to long-term expenses.

- Appearance – Over time, the vivid colors will naturally fade to a more muted, worn finish.

- Sealcoating – Plan on needing a protective seal coat every 2-4 years to maintain the pattern and prevent deterioration.

- Weeds – Since it’s non-porous, weeds can sprout in cracks needing occasional removal.

- Slippery conditions – Asphalt can be slick in wet, icy, or snowy weather until treated or plowed.

Even with these factors, stamped asphalt remains one of the most budget-friendly options for patterned driveways with long-lasting curb appeal.

https://calculatorasphalt.com/stop-pavement-defects-failures/

Alternatives to Stamped Asphalt

While stamped asphalt is an excellent choice, a few other decorative driveway options exist that are worth considering:

Concrete

More durable overall, but prone to cracking and costly repairs. Stamped patterns are not as vivid.

Paver Driveway

Beautiful look but higher upfront costs for materials and labor. Permeable options absorb water.

Gravel

Cheap and low-maintenance, but loose gravel requires edging and displacing easily under tires.

Resin Driveway

Aggregates bound in clear resin create a vibrant, modern finish. Expensive upfront costs.

Wood Planks

Rustic appeal but requires sealing and eventual replacement as planks rot. Not frost-proof.

Asphalt

Traditional asphalt is the most budget-friendly but lacks decorative visual appeal.

Assess your budget, style preferences, maintenance capabilities, and climate to pick the right driveway for your home. An experienced paving contractor can help guide your decision.

Installing a Stamped Asphalt Driveway

Once you decide on stamped asphalt, the installation process involves just a few key steps:

- Prepare the base – Excavate and grade the area, removing all topsoil. Compact at least 6 inches of dense graded aggregate for support.

- Install asphalt – Coat the base with binder and spread 3-4 inches of fresh asphalt across the area. Compact thoroughly.

- Apply color coating – A decorative color coating is sprayed onto the hot asphalt and allowed to soak in for optimal color vibrancy.

- Stamp patterns – Stamping templates are pressed into the warm asphalt using a vibratory plate compactor to imprint the texture evenly.

- Seal and protect – After curing, the stamped asphalt is sealed with a protective coating to complete the installation.

Most projects take 1-3 days with ample time to cure before driving on it. The key is finding an experienced contractor familiar with stamped asphalt. They have the proper tools and expertise to create a durable, properly drained, and beautifully patterned stamped asphalt driveway.

https://calculatorasphalt.com/asphalt-paving/

https://calculatorasphalt.com/calculate-quantity-of-asphalt-in-road/

Maintaining Your Stamped Asphalt Driveway

Like traditional asphalt, preserving your stamped asphalt’s pristine appearance requires some periodic maintenance:

- Sweep often to prevent dirt, rocks, and leaves from accumulating

- Clean oil drips immediately to avoid staining

- Patch small cracks and divots as soon as they appear

- Recoat with elastomeric sealers every 2-4 years

- Avoid plowing snow across the driveway’s surface

- Remove weeds growing in cracks by hand

- Power wash annually to clean thoroughly

- Avoid gasoline and chemical spills which can damage asphalt

With proper care, your stamped asphalt can retain its vibrant pattern for over a decade before needing rejuvenation. Check for problem areas like divots, raveling or alligator cracking annually. Reach out to a paving professional for repairs. With regular upkeep, a stamped asphalt driveway will enhance your home’s curb appeal for years to come.

FAQ

How much does a stamped asphalt driveway cost?

The average cost is $8-12 per square foot including installation. This is 2-3 times cheaper than stamped concrete. An existing asphalt driveway can be stamped for just $2-5 per square foot.

What is the lifespan of a stamped asphalt driveway?

With consistent maintenance like crack sealing and seal coating, a stamped asphalt driveway typically lasts 15-25 years in temperate climates. Harsher winters may require more frequent repairs.

What are the maintenance requirements for stamped asphalt?

Plan to sweep frequently, power wash annually, perform spot repairs as needed, and recoat with a protective sealer every 2-4 years. Avoid chemical spills that can stain. Remove snow carefully without scraping.

Can you get stamped asphalt in different colors?

Yes, tinted color coatings can be applied to the asphalt before stamping to achieve different colors. Popular options include terra cotta, charcoal, burgundy, tan, grey and more. The color will fade over time.

Does stamped asphalt fade in the sun?

Like traditional asphalt, stamped asphalt tends to fade to a more muted, weathered appearance after a few years of sun exposure. Reapplying a protective sealer helps restore the vivid color.

Is stamped asphalt slippery in winter?

It can become slippery when wet or icy until precipitation melts or is removed. Use sand for traction. Apply sealers with anti-slip additives for better winter grip.