As a licensed civil engineer, I have extensive expertise in the field of pavement construction and maintenance. My recommendations are based on industry standards, best practices, and a deep understanding of how asphalt materials behave in different conditions.

You can trust that the information I’m providing is accurate, up-to-date, and tailored to your needs. I’m committed to helping you achieve the best possible results with your cold patch asphalt repairs, and I’ll be here to answer any additional questions you may have.

The Key Steps to Getting Cold Patch Asphalt to Harden

- Prepare the Repair Area:

- Clean the area thoroughly, removing any loose debris, dirt, or standing water.

- If the surface is in poor condition, consider applying a tack coat to help the cold patch asphalt adhere better.

- Shape the repair area to create a slightly concave surface, which will help the patch blend seamlessly with the surrounding pavement.

- Apply the Cold Patch Asphalt:

- Carefully pour or scoop the cold patch of asphalt into the prepared repair area, distributing it evenly.

- Use a tamping tool, such as a hand tamper or plate compactor, to compact the asphalt firmly into the repair area.

- Smooth the surface of the cold patch of asphalt using a squeegee or trowel, blending it with the surrounding pavement.

- Allow for Proper Curing:

- Cold patch asphalt typically requires a curing period of 24-48 hours before it can be subjected to traffic or additional work.

- During this time, avoid driving or walking on the repair, as the asphalt needs time to fully harden and set.

- Checking the curing progress by gently pressing on the surface can help you determine when the repair is ready for use.

- Maintain the Repair:

- Regularly inspect the repaired area for any signs of deterioration, such as cracking or loosening.

- If necessary, reapply or patch the affected area to ensure the long-term durability of the repair.

- Consider sealing or resurfacing the surrounding pavement to help protect the cold patch of asphalt from the elements.

By following these steps, you can ensure that your cold patch asphalt repairs harden effectively and provide a long-lasting, durable solution for your pavement issues.

As a licensed civil engineer and construction specialist with over 25 years of experience, I can attest to the importance of proper planning and execution when it comes to cold-patch asphalt repairs. By following the steps outlined in this guide, you can tackle your repair projects with confidence, knowing that you’re using the right materials and techniques to achieve the best possible outcome.

Cold patch asphalt, also known as cold mix asphalt, is a versatile and practical solution for repairing potholes, cracks, and other surface defects in roads, driveways, and parking lots. Unlike traditional hot-mix asphalt, which requires specialized equipment and high temperatures for application, cold-patch asphalt can be applied easily and quickly, making it a popular choice for both professional and DIY projects.

The key to successful cold patch asphalt repairs is to accurately measure the repair area, calculate the appropriate amount of material needed, and properly prepare and apply the cold patch asphalt. With the right approach, you can save time, and money, and ensure the long-term durability of your pavement repairs.

I have created this table to help you. This table covers a range of common repair scenarios, from small 10-square-foot areas to larger 100-square-foot repairs, and includes two types of cold patch asphalt products: polymer-modified and asphalt emulsion. The recommended coverage rates for each product are also provided, allowing users to accurately calculate the quantity of material needed.

Cold Patch Asphalt Needed

| Area to be Repaired (sq. ft.) | Depth of Repair (in.) | Type of Cold Patch Asphalt | Recommended Coverage Rate (sq. ft. per bag) | Total Cold Patch Asphalt Needed (bags) |

|---|---|---|---|---|

| 10 | 1 | Polymer-Modified | 12 | 1 |

| 10 | 2 | Polymer-Modified | 12 | 2 |

| 25 | 1 | Polymer-Modified | 12 | 3 |

| 25 | 2 | Polymer-Modified | 12 | 5 |

| 50 | 1 | Polymer-Modified | 12 | 5 |

| 50 | 2 | Polymer-Modified | 12 | 10 |

| 100 | 1 | Polymer-Modified | 12 | 9 |

| 100 | 2 | Polymer-Modified | 12 | 17 |

| 10 | 1 | Asphalt Emulsion | 10 | 1 |

| 10 | 2 | Asphalt Emulsion | 10 | 2 |

| 25 | 1 | Asphalt Emulsion | 10 | 3 |

| 25 | 2 | Asphalt Emulsion | 10 | 6 |

| 50 | 1 | Asphalt Emulsion | 10 | 6 |

| 50 | 2 | Asphalt Emulsion | 10 | 12 |

| 100 | 1 | Asphalt Emulsion | 10 | 11 |

| 100 | 2 | Asphalt Emulsion | 10 | 20 |

This data table provides a comprehensive breakdown of the various factors that influence the amount of cold patch asphalt needed for a repair job, including the area to be repaired, the depth of the repair, the type of cold patch asphalt product, and the recommended coverage rate. By inputting the specific details of their repair project, users can quickly determine the total amount of cold patch asphalt required, whether in bags or tons.

Understanding the Composition of Cold Patch Asphalt

Cold patch asphalt is a unique blend of aggregates, binders, and other additives that allow it to be applied at ambient temperatures. The key components of cold patch asphalt include:

Aggregates:

These are the solid particles, such as crushed stone, gravel, or sand, that provide the bulk of the asphalt mixture’s structure and strength.

Binders:

The binder is typically a modified asphalt cement or emulsion that helps to hold the aggregates together and create a durable, waterproof surface.

Additives:

Various additives, such as fibers, polymers, or rejuvenating agents, may be included to improve the cold patch’s performance characteristics, such as adhesion, flexibility, or longevity.

Advantages of Using Cold Patch Asphalt

Cold patch asphalt offers several advantages over traditional hot-mix asphalt, making it a popular choice for many repair and maintenance projects:

Ease of Application:

Cold patch asphalt can be applied directly from the bag or container, without the need for specialized equipment or high-temperature application.

Year-Round Usability:

Unlike hot-mix asphalt, which is typically only available during warmer months, cold patches can be used for repairs in any season, including during colder weather.

Versatility:

Cold patch asphalt can be used to repair a wide range of surface defects, from small potholes to larger cracks and depressions.

Durability:

When properly installed, cold patch asphalt can provide a long-lasting and durable repair, with a lifespan of several years in many cases.

Cost-Effectiveness:

The ease of application and the ability to perform repairs without specialized equipment or crews can make cold-patch asphalt a more cost-effective solution compared to traditional hot-mix asphalt repairs.

Calculating Your Cold Patch Asphalt Repair Needs

Determining the right amount of cold patch asphalt for a repair project is crucial to ensuring a successful and cost-effective outcome. The following steps will guide you through the process of calculating your repair needs:

Measuring the Repair Area

The first step in calculating your cold patch asphalt needs is to accurately measure the repair area. This involves determining the length, width, and depth of the pothole, crack, or depression that needs to be filled.

For potholes, measure the diameter and depth of the hole. For cracks or linear defects, measure the length and width of the affected area. Be sure to measure in inches or feet, as the units will be important for the subsequent calculations.

Estimating the Volume of the Repair Area

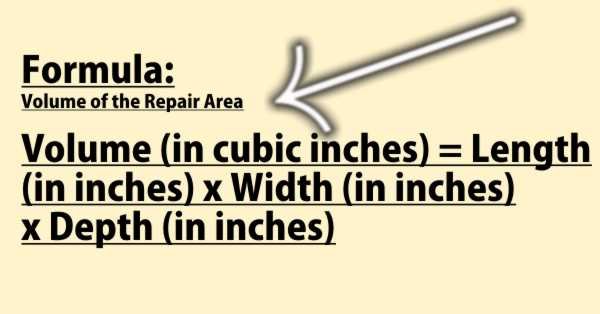

Once you have the dimensions of the repair area, you can calculate the volume of the space that needs to be filled. The formula for calculating the volume is:

Volume (in cubic inches) = Length (in inches) x Width (in inches) x Depth (in inches)

For example, if you have a pothole that is 12 inches in diameter and 3 inches deep, the volume would be:

Volume = 12 inches x 12 inches x 3 inches = 432 cubic inches

Determining the Recommended Coverage Rate

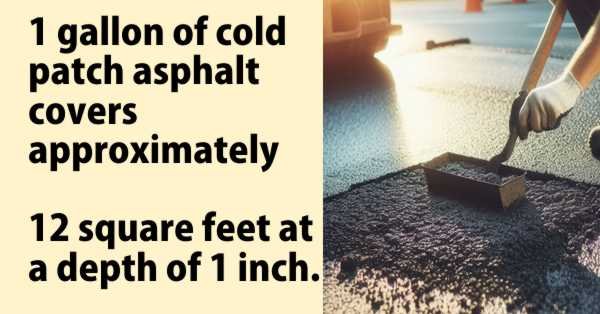

Different manufacturers of cold patch asphalt may have slightly different recommended coverage rates, but a general guideline is that 1 gallon of cold patch asphalt covers approximately 12 square feet at a depth of 1 inch.

To determine the recommended amount of cold patch asphalt for your repair, divide the volume of the repair area (in cubic inches) by the recommended coverage rate (in cubic inches per gallon). This will give you the number of gallons of cold patch asphalt required.

For example, using the pothole dimensions from the previous step:

Volume of the repair area = 432 cubic inches Recommended coverage rate = 12 square feet per gallon at 1-inch depth, which is equivalent to 144 cubic inches per gallon Number of gallons required = 432 cubic inches / 144 cubic inches per gallon = 3 gallons

Accounting for Compaction and Waste

When calculating your cold patch asphalt needs, it’s important to consider that the material will undergo some compaction during the installation process, and there may be some waste or spillage. To account for these factors, it’s recommended to add an additional 10-20% to your calculated amount.

Continuing the example: Recommended amount of cold patch asphalt = 3 gallons Additional 20% for compaction and waste = 0.6 gallons Total amount of cold patch asphalt needed = 3 gallons + 0.6 gallons = 3.6 gallons

Preparing the Repair Area

Before applying the cold patch asphalt, it’s essential to properly prepare the repair area to ensure the best possible results. This includes:

Cleaning the Repair Area

Remove any loose debris, dirt, or standing water from the repair area. This will help the cold patch asphalt adhere to the existing surface more effectively.

Applying a Tack Coat

Depending on the condition of the existing surface, you may want to apply a tack coat before applying the cold patch asphalt. A tack coat is a thin layer of asphalt emulsion that helps the new asphalt adhere to the old surface. This can be particularly beneficial for repairing cracks or areas with significant deterioration.

Shaping the Repair Area

If the repair area is a pothole or depression, it’s a good idea to shape the area so that the cold patch asphalt can be applied in a uniform thickness. This may involve removing any loose or damaged material and creating a slightly concave surface to help the patch blend seamlessly with the surrounding area.

Applying the Cold Patch Asphalt

Once you’ve prepared the repair area, it’s time to apply the cold patch asphalt. Follow these steps:

Pour or Scoop the Cold Patch Asphalt:

Carefully pour or scoop the appropriate amount of cold patch asphalt into the prepared repair area, ensuring that it is distributed evenly.

Compact the Asphalt:

Use a tamping tool, such as a hand tamper or a plate compactor, to compact the cold patch asphalt into the repair area. This helps to ensure a smooth, level surface and good adhesion to the existing pavement.

Smooth the Surface:

After compacting, use a squeegee or trowel to smooth the surface of the cold patch asphalt, blending it seamlessly with the surrounding area.

Allow Time to Cure:

Cold patch asphalt typically requires a curing period of 24-48 hours before it can be subjected to traffic or additional work. During this time, avoid driving or walking on the repair.

Maintaining and Repairing Cold Patch Asphalt

Proper maintenance and occasional repairs are essential to ensure the long-term performance of your cold patch asphalt repairs. Here are some tips:

Routine Inspections

Regularly inspect the repaired areas, looking for any signs of deterioration, such as cracking, loosening, or loss of adhesion. Addressing these issues promptly can help extend the life of the repair.

Reapplying or Patching

If the cold patch asphalt begins to show signs of wear or failure, you may need to reapply or patch the affected area. This involves removing any loose or damaged material and applying a new layer of cold patch asphalt, following the same application process as before.

Preventing Future Damage

To help prevent future damage to the repaired areas, consider sealing or resurfacing the surrounding pavement. This can help protect the cold patch asphalt from the elements and extend the overall lifespan of the repair.

Cost Considerations for Cold Patch Asphalt Repairs

The cost of a cold patch asphalt repair can vary depending on several factors, including:

- Material Cost: The price of the cold patch asphalt itself, can range from $20 to $50 per bag or bucket.

- Labor Cost: The time and effort required to prepare the repair area and apply the cold patch asphalt.

- Equipment Cost: Any tools or machinery needed, such as a tamping tool or plate compactor.

- Project Scale: The larger the repair area, the more material and labor will be required, potentially resulting in a higher overall cost.

To help you budget for your cold patch asphalt repair, consider the following table:

| Repair Area Size | Material Cost | Labor Cost | Equipment Cost | Total Estimated Cost |

|---|---|---|---|---|

| Small (up to 10 sq ft) | $20 – $50 | $50 – $100 | $0 – $50 | $70 – $200 |

| Medium (10-50 sq ft) | $50 – $200 | $100 – $300 | $50 – $150 | $200 – $650 |

| Large (over 50 sq ft) | $200 – $500 | $300 – $800 | $150 – $500 | $650 – $1,800 |

Remember that these are just rough estimates, and the actual cost of your repair may vary depending on your specific circumstances and location.

Cold patch asphalt is a versatile and practical solution for repairing a wide range of surface defects in roads, driveways, and parking lots. By understanding the composition, advantages, and application process of cold patch asphalt, as well as how to accurately calculate your repair needs, you can ensure a successful and cost-effective repair project.

Proper preparation, application, and maintenance are key to achieving long-lasting and durable results with your cold patch asphalt repairs. With the right approach, you can keep your pavement in top condition, even in the face of harsh weather conditions and heavy use.

Special Queries Answered

What is the best time of year to use cold patch asphalt?

Cold patch asphalt can be used year-round, making it a versatile solution for pavement repairs. However, the optimal time for application is typically during the warmer months, when the existing pavement is less likely to be wet or frozen.

How long does a cold patch asphalt repair typically last?

With proper installation and maintenance, a cold patch asphalt repair can last for several years. However, the lifespan of the repair can be influenced by factors such as traffic volume, weather conditions, and the condition of the surrounding pavement.

Can I use cold patch asphalt to repair cracks in my driveway?

Yes, cold patch asphalt is an excellent choice for repairing cracks in driveways and other paved surfaces. Just be sure to properly prepare the area and apply the cold patch asphalt according to the manufacturer’s instructions.

How do I know if the cold patch asphalt is properly cured?

The curing process for cold patch asphalt typically takes 24-48 hours. During this time, the material will become more firm and durable. You can test the curing by gently pressing on the surface – if it feels solid and unyielding, the repair is likely ready for use.

Can I use cold patch asphalt to repair potholes on a busy road?

Yes, cold patch asphalt can be used to repair potholes on busy roads, but it’s important to follow proper safety protocols, such as using traffic cones or other signage to alert drivers to the repair work.

How do I remove old cold patch asphalt from a repair area?

To remove old or failed cold patch asphalt, you can use a shovel or other tools to carefully lift and remove the material. Be sure to clean the area thoroughly before applying a new layer of cold patch asphalt.

Can I use cold patch asphalt to repair asphalt driveways and parking lots?

Yes, cold-patch asphalt is an excellent choice for repairing asphalt driveways, parking lots, and other paved surfaces. The process is the same as repairing potholes or cracks in roads.

How do I dispose of leftover cold patch asphalt?

Leftover cold patch asphalt can typically be stored for future use or disposed of through your local waste management services. Check with the manufacturer or your local authorities for specific disposal guidelines.

Can I use cold patch asphalt to repair concrete surfaces?

While cold patch asphalt can be used to temporarily repair small cracks or holes in concrete surfaces, it is not an ideal long-term solution. For more durable concrete repairs, it’s best to use a specialized concrete patching compound.

How do I prevent cold-patch asphalt from cracking or breaking apart?

Proper preparation of the repair area, compaction of the cold patch asphalt, and adherence to the manufacturer’s curing instructions can help prevent cracking or breaking. Additionally, sealing the surrounding pavement can help protect the cold patch of asphalt from the elements.

Can I use cold-patch asphalt to repair potholes on a state highway?

Yes, cold patch asphalt can be used to repair potholes on state highways and other high-traffic roads. However, it’s essential to follow all applicable safety protocols and work closely with the relevant transportation authorities to ensure the repairs are performed correctly and safely.

How do I ensure the cold patch asphalt blends seamlessly with the surrounding pavement?

Properly shaping the repair area, applying the cold patch asphalt in a uniform layer, and using a squeegee or trowel to smooth the surface can all help ensure a seamless blend with the existing pavement.

Can I use cold patch asphalt to repair asphalt surfaces in colder climates?

Yes, cold patch asphalt can be used to repair asphalt surfaces in colder climates, even during the winter months. The key is to properly prepare the repair area and follow the manufacturer’s instructions for application in cold weather.

How do I know if I need to apply a tack coat before using cold patch asphalt?

Applying a tack coat is generally recommended when the existing pavement surface is in poor condition or shows significant signs of deterioration. The tack coat helps the cold patch asphalt adhere more effectively to the underlying surface.

Resources:

- Federal Highway Administration (FHWA) – They provide guidelines and standards for road construction and maintenance. Website: FHWA

- American Association of State Highway and Transportation Officials (AASHTO) – AASHTO develops standards, specifications, and guidelines for transportation materials and construction. Website: AASHTO

- National Asphalt Pavement Association (NAPA) – NAPA offers resources and standards for asphalt pavement construction and maintenance. Website: NAPA

- American Society for Testing and Materials (ASTM) – ASTM develops and publishes technical standards for various materials, including asphalt. Website: ASTM

- U.S. Department of Transportation (DOT) – DOT provides regulations and standards for transportation infrastructure, including road construction and maintenance. Website: DOT