Parking Lot Striping Costs

Based on my 25+ years of experience in the industry, here are some general cost ranges for standard parking lot striping projects:

| Project Size | Cost per Linear Foot |

|---|---|

| Small Lot (under 5,000 sq ft) | $1.50 – $3.00 |

| Medium Lot (5,000 – 20,000 sq ft) | $1.00 – $2.50 |

| Large Lot (over 20,000 sq ft) | $0.75 – $2.00 |

These prices can vary depending on location, materials used, and the specific requirements of each job. It’s always best to get custom quotes from experienced parking lot striping contractors.

The typical cost for parking lot striping can vary significantly depending on the specific type of line being applied. On average, the cost per linear foot typically ranges from $0.20 to $1.00, with the exact price depending on the required line work.

For a single parking stall line, the average cost is around $0.35 per linear foot.

For ground painting, such as fire lanes or cross-hatching, the price is generally between $0.30 and $0.50 per linear foot.

Curb painting, often done in red or yellow, tends to be on the higher end, with costs ranging from $0.85 to $1.20 per linear foot.

I have created this detailed table comparing the cost differences between manual and machine-based parking lot striping on a per linear foot basis:

Manual vs. Machine-Based Parking Lot Striping Costs

| Cost Component | Manual Application | Machine Application |

|---|---|---|

| Material Cost (Paint, Thermoplastic, etc.) | $0.40 – $0.60 per LF | $0.40 – $0.60 per LF |

| Labor Cost (Crew Hourly Rate x Time per LF) | $0.50 – $1.00 per LF | $0.30 – $0.60 per LF |

| Equipment Cost (Rental, Maintenance, etc.) | $0.05 – $0.15 per LF | $0.10 – $0.25 per LF |

| Overhead & Profit (20-30% of Total Costs) | $0.19 – $0.53 per LF | $0.16 – $0.43 per LF |

| Total Cost per Linear Foot | $1.14 – $2.28 | $0.96 – $1.88 |

Key Differences:

- Labor Costs: Manual application requires more labor-intensive work, leading to higher labor costs per linear foot compared to machine-based striping.

- Equipment Costs: Machine-based striping requires specialized equipment like line-striping machines, which have a higher rental or usage cost per linear foot.

- Efficiency: Machine-based striping is generally more efficient, allowing for faster application and lower labor costs per linear foot.

- Consistency: Machine-based striping typically provides a more consistent, high-quality finish compared to manual application.

Considerations:

- The actual cost difference between manual and machine-based striping will depend on the specific project, location, and the expertise of the contractor.

- Larger parking lots may see a more significant cost advantage for machine-based striping due to economies of scale.

- Manual application may be more suitable for smaller, less complex projects or in areas with limited access for striping equipment.

- The choice between manual or machine-based striping should also consider factors like the desired finish quality, project timeline, and the contractor’s capabilities.

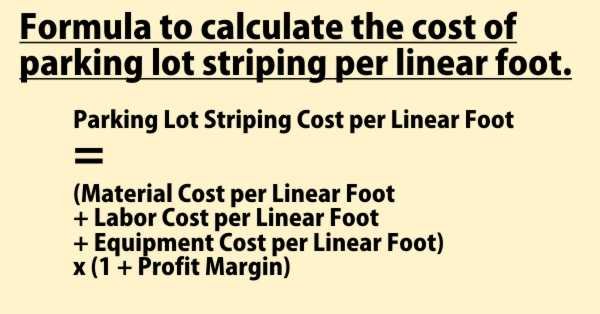

Here is a formula to calculate the cost of parking lot striping per linear foot based on my experience

Parking Lot Striping Cost per Linear Foot = (Material Cost per Linear Foot + Labor Cost per Linear Foot + Equipment Cost per Linear Foot) x (1 + Profit Margin)

Where:

Material Cost per Linear Foot:

- This includes the cost of the striping paint, thermoplastic, or other materials used per linear foot.

Labor Cost per Linear Foot:

- This includes the hourly labor rate of the striping crew multiplied by the time required to stripe one linear foot.

Equipment Cost per Linear Foot:

- This includes the rental or usage cost of any specialized equipment like line-striping machines, divided by the linear feet of striping completed.

Profit Margin:

- This is the percentage markup added by the contractor to cover overhead and profit. Typical profit margins range from 10-30%.

For example, let’s say:

- Material Cost per Linear Foot = $0.40

- Labor Cost per Linear Foot = $0.30

- Equipment Cost per Linear Foot = $0.10

- Profit Margin = 20%

Then the total Parking Lot Striping Cost per Linear Foot would be:

(0.40 + 0.30 + 0.10) x (1 + 0.20) = $0.96 per linear foot

This formula allows you to account for all the key cost components and apply an appropriate profit margin to arrive at the final price per linear foot that the contractor would charge.

The actual costs can vary widely based on the specific project, location, materials used, labor rates, and other factors. However this formula provides a general framework for calculating parking lot striping costs.

Factors Influencing Parking Lot Striping Prices

Material Costs

The cost of the actual striping paint or thermoplastic material is one of the primary factors in determining the overall price of a parking lot striping project. High-quality paint or thermoplastic can be more expensive upfront but often provides better durability and longevity.

Labor Costs

The labor involved in properly prepping the surface, applying the striping, and cleaning up afterward all add to the overall cost. Experienced striping crews can work efficiently, but labor rates in your local market will impact the final price.

Project Size and Complexity

Larger parking lots with more linear feet of striping will generally cost more overall, but the price per linear foot may be lower due to economies of scale. Complex layouts, tight spaces, or the need for specialized equipment can also increase the cost.

How to Estimate Parking Lot Striping Costs

Measuring the Parking Lot

The first step in estimating striping costs is accurately measuring the parking lot. This involves determining the total square footage as well as the linear feet of each type of stripe (parking stalls, directional arrows, handicap symbols, etc.).

Calculating Material Needs

Once you have the measurements, you can estimate the amount of striping paint or thermoplastic material required. Generally, you’ll need about 12-15 gallons of paint or 30-40 linear feet of thermoplastic per 1,000 square feet of striping.

Factoring in Labor and Equipment

In addition to material costs, you’ll need to account for the labor required to complete the job, as well as any specialized equipment like line-striping machines. Labor rates can vary widely depending on your local market.

Obtaining Quotes from Contractors

For the most accurate pricing, it’s best to get quotes from experienced parking lot striping contractors in your area. They can provide a detailed breakdown of all the costs involved and offer recommendations on the best materials and techniques for your specific project.

Types of Parking Lot Striping Materials

Acrylic-Based Traffic Paint

Acrylic-based paint is a common and cost-effective option for parking lot striping. It’s easy to apply and dries quickly, but may require more frequent reapplication compared to other materials.

Solvent-Based Traffic Paint

Solvent-based paints offer better durability and longer-lasting performance than acrylic paints, but they can be more expensive and have stronger odors during application.

Thermoplastic Pavement Markings

Thermoplastic is a durable, long-lasting material that is heated and applied to the pavement. It’s more expensive upfront but can provide 5-10 years of service before needing replacement.

Preformed Thermoplastic Tape

Preformed thermoplastic tapes are a quick and convenient option, as they can be simply applied to the pavement surface without the need for heating or specialized equipment.

Parking Lot Striping Best Practices

Surface Preparation

Proper surface preparation is crucial for ensuring the striping adheres properly and lasts as long as possible. This may include cleaning, repairing cracks or potholes, and priming the surface.

Proper Application Techniques

Using the right tools and techniques, such as specialized line-striping machines and following manufacturer guidelines, can make a big difference in the final appearance and durability of the striping.

Maintenance and Restriping

Regular maintenance, such as cleaning the lot and addressing any fading or wear in the striping, can help extend the life of your parking lot markings. Restriping may be necessary every 2-5 years, depending on the materials used and the level of traffic.

The Benefits of Professional Parking Lot Striping

Improved Safety and Functionality

Well-maintained parking lot striping helps guide traffic flow, delineate parking spaces, and ensure accessibility for handicapped and emergency vehicles, which can enhance safety for both drivers and pedestrians.

Enhanced Curb Appeal and Property Value

A freshly striped, well-organized parking lot can significantly improve the overall appearance and perceived value of a commercial property, making it more attractive to potential customers and tenants.

Compliance with Local Regulations

Many municipalities have specific requirements for parking lot striping and markings, and hiring a professional contractor can help ensure your property complies with these regulations.

Determining the right price for parking lot striping can be a complex process, with numerous factors to consider. By understanding the key cost drivers, preparing the surface properly, and working with experienced contractors, you can ensure your parking lot striping project is completed efficiently and cost-effectively.

As an experienced civil engineer and construction specialist with over 25 years of expertise in asphalt materials, specifications, and roadway construction, I’ve had the opportunity to work on countless parking lot striping projects throughout my career. I always strive to provide my clients with transparent, accurate pricing and high-quality workmanship to help them maintain safe, attractive, and compliant parking areas.

If you have any other questions about parking lot striping costs or best practices, please don’t hesitate to reach out. I’m happy to share my knowledge and help you make the best decisions for your property.