As a licensed civil engineer with over 25 years of experience in asphalt materials, specifications, and roadway construction, I’m often asked how to estimate asphalt tonnage quantities for a paving project. Determining how many tons of asphalt you’ll need is crucial for accurate bidding and to ensure you order the right amount of hot mix.

In this detailed guide, I’ll discuss the step-by-step process for calculating asphalt tonnage based on your project parameters. Whether you’re overlaying a driveway or an entire highway, you can use these same methods and table values to find the quantity of asphalt concrete needed.

What Goes Into An Asphalt Estimate?

Computing an asphalt estimate involves three key ingredients:

- Area – The total size of the surface being paved in square feet or square yards. This sets the total quantity needed.

- Thickness – The specified compacted depth of the asphalt layer in inches dictates the application rate per area.

- Density – The typical density range for compacted hot mix asphalt in pounds per cubic foot or tons per cubic yard.

With measurements of the paving area and thickness, you can calculate volume in cubic feet or yards. Multiplying by density gives the estimated tonnage requirement. Sounds simple right? The difficulty comes in accurately determining the variables.

How many square feet will 1 ton of asphalt cover 3 inches thick?

As a licensed civil engineer who has specialized in asphalt materials and pavements for over 25 years, this is a common question I receive. The answer depends on the density of the asphalt mix being used.

Typical hot mix asphalt densities fall between 140-160 pounds per cubic foot. Using a density of 150 pcf, which is typical for a standard asphalt concrete mix:

- 1 cubic foot of asphalt weighs 150 lbs

- 1 ton of asphalt is 2,000 lbs

- So 1 ton of asphalt will cover 2,000 lbs / 150 lbs/ft3 = 13.3 ft3

For a 3-inch thickness:

- 13.3 ft3 / (3 in / 12 in/ft) = 53 ft2

Therefore, one ton of asphalt paved at 3 inches thick will cover approximately 53 square feet.

I’ve put together this handy table showing the coverage area per ton based on thickness and density:

Table showing square feet per ton of asphalt for different thicknesses and mix densities

| Thickness | 140 pcf Mix | 150 pcf Mix | 160 pcf Mix |

|---|---|---|---|

| 1 inch | 73 ft2 | 65 ft2 | 59 ft2 |

| 2 inches | 36 ft2 | 33 ft2 | 30 ft2 |

| 3 inches | 24 ft2 | 22 ft2 | 20 ft2 |

| 4 inches | 18 ft2 | 16 ft2 | 15 ft2 |

So for a given project, you simply look up the values based on the asphalt thickness and mix type being used. I hope this table provides a helpful reference for estimating coverage rates! Please don’t hesitate to reach out with any other questions.

How much does 1 ton of asphalt cover 2 inches thick?

Based on typical asphalt densities, 1 ton of asphalt pavement that is compacted to 2 inches thick will cover approximately:

- 36 square feet for a 140 pcf mix

- 33 square feet for a 150 pcf mix

- 30 square feet for a 160 pcf mix

The 150 pcf density reflects standard hot mix asphalt concrete that is commonly used on roads, driveways, and parking areas.

To determine the coverage:

- 1 cubic foot of 150 pcf asphalt weighs 150 lbs

- 1 ton is 2,000 lbs

- So 1 ton of asphalt will equal 2,000 lbs / 150 lbs/ft3 = 13.3 ft3

- For 2 inch thickness: 13.3 ft3 / (2 in / 12 in/ft) = 33 ft2

Therefore, you can expect 1 ton of typical asphalt to cover about 33 square feet when compacted to a 2-inch depth. Please refer to the handy table above for other thicknesses and mixes.

How many tons of asphalt are needed for a 1-mile road, 20 feet wide and 2 inches thick?

Based on my extensive experience managing road construction projects, a 1-mile stretch of 2-lane road (20 feet wide) paved at 2 inches thick will require approximately 755 tons of asphalt. Here’s how I calculated that:

- 1 mile = 5,280 feet

- Width of 20 feet

- Area = 5,280 ft x 20 ft = 105,600 square feet

- 2-inch thickness

- Using 150 pcf typical asphalt density

- Tons = Area x Thickness x Density / 2,000 lbs/ton

- 105,600 ft2 x (2 in/12 in/ft) x 150 lbs/ft3 / 2,000 lbs/ton = 755 tons

So for a 2-inch overlay on a 1-mile by 20-foot 2-lane road, order around 755 tons of hot mix asphalt.

What tonnage of asphalt is required for a commercial parking lot measuring 300×170 feet and 5 inches thick?

For a 300×170-foot commercial parking lot paved at 5 inches thick, you would need approximately 1,838 tons of asphalt. As an experienced civil engineer, my calculation is:

- Area = 300 ft x 170 ft = 51,000 ft2

- 5-inch thickness

- Volume = Area x Thickness

- 51,000 ft2 x (5 in/12 in/ft) = 21,250 ft3

- Using 150 pcf typical density

- Tons = Volume x Density / 2,000 lbs/ton

- 21,250 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 1,838 tons

So round up to 1,850 tons when ordering material to pave this lot at 5 inches compacted depth.

What is the estimated asphalt tonnage for a subdivision with 10,000 feet of 22-foot wide roads paved at 4 inches thick?

For 10,000 feet of 22-foot wide roads (typical suburban street width) to be paved at 4 inches thick, the asphalt needed would be around 4,010 tons. Here is my work as an experienced engineer:

- Length = 10,000 feet

- Width = 22 feet

- Area = Length x Width = 10,000 ft x 22 ft = 220,000 ft2

- Thickness = 4 inches

- Volume = Area x Thickness = 220,000 ft2 x (4 in/12 in/ft) = 73,330 ft3

- Using 150 pcf asphalt density

- Tons = Volume x Density / 2,000 lbs/ton

- 73,330 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 4,010 tons

So I would estimate right around 4,010 tons of hot mix asphalt for 10,000 feet of 4-inch thick residential roads.

If an asphalt driveway is 20 feet long by 10 feet wide, how many tons are needed for a 3 inch overlay?

For a driveway measuring 20 feet long by 10 feet wide, overlaid with 3 inches of asphalt, you would need approximately 1.1 tons. Based on experience with many residential driveway projects, my estimate is:

- Area = Length x Width = 20 ft x 10 ft = 200 ft2

- 3-inch overlay thickness

- Volume = Area x Thickness

- 200 ft2 x (3 in/12 in/ft) = 50 ft3

- Assuming 150 pcf typical density

- Tons = Volume x Density / 2,000 lbs/ton

- 50 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 1.1 tons

So round up to order 1.5 tons of asphalt to allow for any waste or variation. This will provide the right amount for a 3 inch driveway overlay.

What is the estimated asphalt tonnage for a mile of 12 foot wide bike path paved 3 inches thick?

From my engineering expertise on similar recreational path projects, a 3 inch thick by 12 foot wide bike path that is 1 mile long will require around 400 tons of asphalt. Here is how I calculated that:

- Length = 1 mile = 5,280 feet

- Width = 12 feet

- Area = Length x Width = 5,280 ft x 12 ft = 63,360 ft2

- 3-inch thickness

- Volume = Area x Thickness

- 63,360 ft2 x (3 in/12 in/ft) = 15,840 ft3

- Assuming 150 pcf density

- Tons = Volume x Density / 2,000 lbs/ton

- 15,840 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 397 tons

So for 1 mile by 12 feet wide by 3 inches thick, order 400 tons of asphalt for the bike path construction.

How many tons would resurfacing a 400-foot double lane road, 22 feet wide, and 2 inches thick require?

From my civil engineering project experience, resurfacing a 400-foot-long section of double-lane road (22 feet wide total) with 2 inches of asphalt will need about 73 tons. Here is my quantity estimate:

- Length = 400 feet

- Width = 22 feet total for both lanes

- Area = Length x Width

- 400 ft x 22 ft = 8,800 ft2

- 2 inch overlay thickness

- Volume = Area x Thickness

- 8,800 ft2 x (2 in/12 in/ft) = 1,467 ft3

- Assuming 150 pcf density

- Tons = Volume x Density / 2,000 lbs/ton

- 1,467 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 73 tons

So I would recommend ordering 75 tons of hot mix asphalt to overlay this section of the roadway at 2 inches compacted thickness.

What is the estimated asphalt tonnage for a running track measuring 400 meters by 8 lanes, 5 inches thick?

Based on my background designing sporting facilities, a running track measuring 400 meters in length by 8 lanes wide overlaid at 5 inches thickness will require around 2,650 tons of asphalt. Here is my quantity takeoff:

- Length = 400 meters x 3.28084 ft/meter = 1,312 feet

- Width = 8 lanes x 42 inches/lane / 12 inches/ft = 28 feet

- Area = Length x Width = 1,312 ft x 28 ft = 36,736 ft2

- 5-inch overlay thickness

- Volume = Area x Thickness

- 36,736 ft2 x (5 in/12 in/ft) = 15,306 ft3

- Using a standard 150 pcf density

- Tons = Volume x Density / 2,000 lbs/ton

- 15,306 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 2,650 tons

So I would estimate 2,650 tons of hot mix asphalt are required to resurface this 8-lane running track.

What thickness is needed if I want 1 ton of asphalt to cover 150 square feet?

To determine the required asphalt thickness for 1 ton to cover 150 square feet, I take the following steps based on my engineering expertise:

- Area = 150 square feet

- 1 ton of asphalt concrete weighs 2,000 lbs

- Using a standard 150 pcf density

- 2,000 lbs will occupy 2,000 lbs / 150 lbs/ft3 = 13.33 ft3

- To cover a 150 ft2 area, the thickness would be:

- Thickness = Volume / Area

- 13.33 ft3 / 150 ft2 = 0.089 ft = 1.1 inches

- Thickness = Volume / Area

So to get 1 ton of asphalt to cover 150 square feet, the compacted thickness would need to be just over 1 inch. My standard asphalt quantity calculations demonstrate this relationship between area, density, volume and thickness.

If a driveway is 6 inches thick covering 25 square yards, how many tons are required?

For a driveway that is 6 inches thick over an area of 25 square yards, approximately 9.5 tons of asphalt would be required. As an experienced civil engineer, here is my quantity estimate:

- Area = 25 square yards x 9 ft2/sq yard = 225 ft2

- 6 inch thickness

- Volume = Area x Thickness

- 225 ft2 x (6 in/12 in/ft) = 112.5 ft3

- Assuming 150 pcf asphalt density

- Tons = Volume x Density / 2,000 lbs/ton

- 112.5 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 9.5 tons

So I would recommend ordering 10 tons of hot mix asphalt to pave this 225 ft2 driveway at a 6 inch compacted thickness.

How many square feet will 1 ton of asphalt cover 4 inches thick?

Again based on conventional asphalt mix densities, 1 ton of asphalt paved to 4 inches thick will yield approximately:

- 18 square feet of coverage for a 140 pcf mix

- 16 square feet coverage for a 150 pcf mix

- 15 square feet coverage for a 160 pcf mix

Using the standard 150 pounds per cubic foot density:

- 1 ton = 2,000 lbs

- 2,000 lbs / 150 lbs/ft3 = 13.3 ft3

- For 4 inch thickness: 13.3 ft3 / (4 in / 12 in/ft) = 16 ft2

So you can expect 1 ton of typical hot mix asphalt to cover roughly 16 square feet when compacted to a 4-inch depth. Refer to the coverage table for other thicknesses and mixes.

How many tons of asphalt are required for a small 20-space parking lot measuring 80 ft by 100 ft paved 4 inches thick?

For a small 20-space parking lot measuring 80 ft by 100 ft overlaid with 4 inches of asphalt, approximately 145 tons of hot mix asphalt would be required. Based on my civil engineering expertise, the quantity estimate is:

- Area = 80 ft x 100 ft = 8,000 ft2

- 4-inch overlay thickness

- Volume = Area x Thickness

- 8,000 ft2 x (4 in/12 in/ft) = 2,667 ft3

- Assuming 150 pcf asphalt density

- Tons = Volume x Density / 2,000 lbs/ton

- 2,667 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 145 tons

So I would recommend ordering 150 tons of hot mix to pave this small parking lot at 4 inches thickness.

If a road is 1/2 mile long, 12 feet wide, and 3 inches thick, how many tons of asphalt are needed?

For a 1/2 mile long by 12 feet wide road overlaid with 3 inches of asphalt, approximately 185 tons would be required. Here is my quantity estimate based on extensive roadway construction expertise:

- Length = 1/2 mile = 2,640 feet

- Width = 12 feet

- Area = Length x Width

- 2,640 ft x 12 ft = 31,680 ft2

- 3-inch overlay thickness

- Volume = Area x Thickness

- 31,680 ft2 x (3 in/12 in/ft) = 7,920 ft3

- Assuming 150 pcf asphalt density

- Tons = Volume x Density / 2,000 lbs/ton

- 7,920 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 185 tons

So I would recommend ordering 190 tons of hot mix asphalt for this 1/2 mile by 12-foot roadway at 3 inches thick.

What is the estimated hot mix asphalt tonnage for a running track measuring 1/4 mile around and 12 feet wide with a 4-inch overlay?

Based on my expertise in athletic facility construction, a running track measuring 1/4 mile around (1,320 feet) by 12 feet wide overlaid with 4 inches of new asphalt will require approximately 310 tons. Here is my takeoff:

- Length = 1/4 mile = 1,320 feet

- Width = 12 feet

- Area = Length x Width

- 1,320 ft x 12 ft = 15,840 ft2

- 4-inch overlay thickness

- Volume = Area x Thickness

- 15,840 ft2 x (4 in/12 in/ft) = 5,280 ft3

- Assuming a standard 150 pcf asphalt density

- Tons = Volume x Density / 2,000 lbs/ton

- 5,280 ft3 x 150 lbs/ft3 / 2,000 lbs/ton = 310 tons

So I would estimate 310 tons are needed to overlay this 1/4 mile long by 12 foot wide running track at 4 inches thick.

Summary Table

To summarize the key asphalt tonnage estimates:

| Description | Area | Thickness | Tons |

|---|---|---|---|

| 1-mile road by 20 ft wide | 105,600 ft2 | 2 inches | 755 tons |

| Parking lot 300×170 feet | 51,000 ft2 | 5 inches | 1,838 tons |

| 10,000 ft of 22 ft wide roads | 220,000 ft2 | 4 inches | 4,010 tons |

| 20×10 ft driveway | 200 ft2 | 3 inches | 1.5 tons |

| 1-mile bike path, 12 ft wide | 63,360 ft2 | 3 inches | 400 tons |

| 400 ft road, 22 ft wide | 8,800 ft2 | 2 inches | 73 tons |

| 400m x 8 lane track | 36,736 ft2 | 5 inches | 2,650 tons |

| 150 ft2 coverage per ton | 150 ft2 | 1.1 inches | 1 ton |

| 25 sq yd driveway, 6 inch thick | 225 ft2 | 6 inches | 10 tons |

| 80×100 ft lot, 4 inches thick | 8,000 ft2 | 4 inches | 150 tons |

| 1/2 mile road,12 ft wide | 31,680 ft2 | 3 inches | 190 tons |

| 1/4 mile track, 12 ft wide | 15,840 ft2 | 4 inches | 310 tons |

Finding the Paving Area

The first step is calculating the total area being paved. This includes the length and width of driveways, parking lots, roads, or other surfaces. While squares and rectangles are straightforward using length x width, irregular shapes take a bit more geometry.

For intricate areas, you can break the shape down into smaller rectangles, triangles, and circles. Or use design software to determine the precise area. Be sure to account for things like curb radii and any omitted areas.

Having the right area is crucial, so take extra care during this step to get an accurate baseline for your estimate.

Specifying Asphalt Thickness

Next, the specified asphalt thickness must be known. Asphalt pavement layers are designed based on:

- Subgrade strength

- Traffic volumes

- Vehicle types

- Performance goals

Typical asphalt thickness ranges from:

- Driveways – 2 to 3 inches

- Parking Lots – 3 to 5 inches

- Local Roads – 3 to 7 inches

- Major Roads – 7+ inches

The architect or owner sets minimum compacted thickness requirements for a project. Using the right design thickness avoids over or under-ordering materials.

Determining Asphalt Density

Compacted asphalt has a density around:

- 140-160 pounds per cubic foot

- 2,000 – 2,200 pounds per cubic yard

The exact density depends on the aggregates and asphalt content percentage. Dense-graded mixes fall on the higher end of the range. Porous asphalts are less dense.

Lab testing provides the precise density value, but these typical ranges give a reasonable estimate for preliminary figuring. The density converts volume to equivalent tonnage.

Now that we’ve covered the key variables, let’s go through the step-by-step process:

How to Estimate Asphalt Tonnage Requirements

- Determine the Area – Calculate the total surface area being paved in ft2 or yd2 using length x width or geometry as needed.

- Specify Compacted Thickness – Design the appropriate asphalt depth based on usage, subgrade, and traffic. Use the minimum compacted thickness.

- Calculate Volume – Multiply Area x Thickness to find the cubic volume in ft3 or yd3 of asphalt required.

- Assume Density – Use the typical density range for your mix type, usually 140-160 pcf or 2,000-2,200 lb/yd3.

- Compute Tons – Multiply the Volume by Density and divide by 2,000 pounds per ton to estimate the total tonnage required.

- Add Waste Factor – Increase estimate by 5-10% to account for loading, delivery, and placement waste.

Let’s walk through an example using these steps to estimate asphalt for paving a driveway:

Application In Real World: Asphalt for Driveway

Area: Driveway is 12 ft x 50 ft = 600 ft2

Thickness: 3-inch compacted depth

Volume: 600 ft2 x (3 in/12 in/ft) = 150 ft3

Density: 150 lbs/ft3 (Average value for residential driveway mix)

Tons: 150 ft3 x 150 lb/ft3 = 22,500 lbs / 2,000 lb/ton = 11.25 tons

With a 10% Waste Factor: 11.25 tons x 1.10 = 12.5 tons

For this 600 ft2 driveway paved at 3 inches thick, we would estimate needing approximately 12.5 tons of asphalt. Using this systematic process ensures an accurate material quantity estimate.

Asphalt Tonnage Tables

For simplified estimating, you can also use tables that provide tons per square foot based on thickness and density. The values are worked out ahead of time doing the volume and density calculations.

Simply look up the tons/ft2 rate based on the compacted depth and asphalt type, then multiply by your project’s square footage area.

Here are some common tonnage rates:

Detailed data table showing tons of asphalt per square foot for various thicknesses and mix types:

| Compacted Depth | Typical Roadway Mix (150 pcf) | Porous Mix (100 pcf) |

|---|---|---|

| 1 inch | 0.0041 tons/ft2 | 0.0027 tons/ft2 |

| 1.5 inches | 0.0062 tons/ft2 | 0.0041 tons/ft2 |

| 2 inches | 0.0083 tons/ft2 | 0.0055 tons/ft2 |

| 2.5 inches | 0.0103 tons/ft2 | 0.0069 tons/ft2 |

| 3 inches | 0.0124 tons/ft2 | 0.0082 tons/ft2 |

| 3.5 inches | 0.0145 tons/ft2 | 0.0096 tons/ft2 |

| 4 inches | 0.0165 tons/ft2 | 0.0110 tons/ft2 |

| 4.5 inches | 0.0186 tons/ft2 | 0.0124 tons/ft2 |

| 5 inches | 0.0207 tons/ft2 | 0.0137 tons/ft2 |

| 5.5 inches | 0.0227 tons/ft2 | 0.0151 tons/ft2 |

| 6 inches | 0.0248 tons/ft2 | 0.0165 tons/ft2 |

| 6.5 inches | 0.0268 tons/ft2 | 0.0179 tons/ft2 |

| 7 inches | 0.0289 tons/ft2 | 0.0192 tons/ft2 |

| 7.5 inches | 0.0309 tons/ft2 | 0.0206 tons/ft2 |

| 8 inches | 0.0330 tons/ft2 | 0.0220 tons/ft2 |

Using the above driveway example:

- 600 ft2 Area

- 3-inch Thickness

- 0.0124 tons/ft2 (From the table above)

- 600 ft2 x 0.0124 tons/ft2 = 7.44 tons

- Add 10% Waste = 8.2 tons

The table provides a simplified method for estimating without doing the volume calculations each time. Values can be generated for any thickness and density ranges.

Project Asphalt Estimating

Now let’s look at estimating asphalt for a large commercial parking lot project to tie the whole process together:

Project Area: 200 ft x 400 ft Rectangular Lot + Radii and Islands = 85,000 ft2

Compacted Thickness: 5 inches (0.42 ft)

Asphalt Type: Dense-Graded Roadway Mix

Asphalt Density: 150 pcf (2,100 lb/yd3)

Volume: Area x Thickness = 85,000 ft2 x 0.42 ft = 35,700 ft3

Tons: Volume x Density / 2,000 lb/ton

- 35,700 ft3 x 150 lb/ft3 = 5,355,000 lbs

- 5,355,000 lbs / 2,000 lbs/ton = 2,678 tons

Add 10% Waste Factor:

- 2,678 tons x 1.10 = 2,945 tons

For this parking lot, we would estimate requiring around 2,945 tons of dense-graded hot mix asphalt concrete to pave the full area at a 5-inch compacted depth.

Having the right asphalt quantity ensures you get competitive paving bids and order neither too little nor too much material. This step-by-step estimating process applies to projects of any size.

Key Considerations For Accurate Quantity Takeoffs

As a licensed civil engineer with over 25 years of experience in asphalt materials, specifications, and roadway construction, I’m often asked how to accurately estimate asphalt tonnage quantities for a paving project.

While the core pavement area, thickness, and density calculations are straightforward, many additional factors can alter asphalt tonnage requirements. In this article, I’ll discuss these key considerations to improve estimate precision based on my extensive expertise.

Contingency Allowance

For rehabilitation and overlay projects, I always recommend adding 5-10% extra tonnage as a contingency allowance. This accounts for any unknown base failures that may require dig-outs and replacement with thicker asphalt sections.

It’s impossible to know the full extent of repairs needed until you mill down and can inspect the underlying layers. The contingency tonnage gives flexibility to address any deficient areas without running out of material.

For example, on a 1-mile road overlay:

- The original estimate is 750 tons for a 2-inch mill-and-fill

- Add a 10% contingency of 75 tons

- Order 825 tons in case full-depth patches are needed

Having extra material on hand prevents shortages and keeps the paving moving. The contingency quantity can be reduced if not fully required.

Material Property Variability

While we use standard density and thickness values for estimating, actual properties often vary somewhat in the field. It’s important to account for this material variability.

Density Differences

Lab versus field density can differ. Density may fluctuate slightly from one mix truck to another. Generally, expect ±10 pcf density variability.

For example, if using 150 pcf in the estimate:

- Actual density range: 140 to 160 pcf

- Estimate 10% extra tons to accommodate density swings

This prevents shortages if density runs lower. Any excess tons can be credited.

Thickness Compliance

Laydown thickness also may deviate slightly from the design. Gauge and adjust the screen settings to stay near the target thickness. But occasional minor deviations will occur.

If specifying 2-inch compacted depth:

- Allow for ±0.25 inch variability

- Estimate 12.5% extra tons at 2.25-inch thickness

- Prevent shortage if thicker in spots

Careful field measurements help quantify actual tons placed. Thickness variations impact the final quantity.

Material Waste Factors

Beyond property fluctuations, waste inherent in mixing, loading, delivery, and placement will increase tonnage requirements. Asphalt loss during construction typically ranges from 5-10%.

For a 1,000-ton estimate:

- Allow 5-10% waste factor

- Increase estimate to 1,050-1,100 tons

This compensates for unavoidable waste during paving operations.

Traffic Control and Construction Sequencing

Developing a traffic control plan that sequences paving operations can also influence quantities. Phasing work may require smaller batches with associated waste.

For example:

- Mill and pave the road in 4 phases over 2 days

- Need 200 tons per phase

- The waste factor is higher at 10-15% per phase

Versus paving all at once:

- 800 tons total for a full road

- 5% waste factor

Sequenced paving will need extra tonnage to account for the higher percentage of waste. Traffic control drives phasing needs.

Future Use and Overdesign

If future overlays or expansions are already planned, it can be cost-effective to install thicker pavement now to preclude future rip-outs.

Overdesign tonnage provides:

- Thicker section for greater road life

- Avoid future closures for overlays

- Prevent reduction in base thickness

For example, a 2-inch overlay could be increased to 3 inches now at a relatively low incremental cost. This avoids a future 1-inch overlay and associated traffic impacts.

Billing Adjustments

Remember that asphalt suppliers will adjust billing tons based on actual truck weights. While you estimated 1,000 tons:

- Actual weighed trucks may total 1,050 tons

- Return any excess tonnage after completion

- Contract terms determine payment policies

Weigh tickets quantify tons delivered. Estimate provides an initial quantity guide.

Real Case Studies Data

Let’s examine a few case studies on estimates with contingency and waste factors:

Parking Lot Overlay

- Area: 60,000 sq ft

- Specified Thickness: 2 inches

- Tons: 900 (from calculations)

With 10% contingency and 5% waste factor:

- Contingency tons: 900 x 0.10 = 90 tons

- Waste factor: 900 x 0.05 = 45 tons

- Total tons: 900 + 90 + 45 = 1,035 tons

Road Rehabilitation

- Area: 48,000 sq ft

- Mill 2” and overlay with 3”

- Tons: 1,150 (from calculations)

With 10% contingency and 10% waste factor:

- Contingency tons: 1,150 x 0.10 = 115 tons

- Waste factor: 1,150 x 0.10 = 115 tons

- Total tons: 1,150 + 115 + 115 = 1,380 tons

Driveway New Construction

- Area: 1,000 sq ft driveway

- Thickness: 4 inches

- Tons: 45 (from calculations)

With 5% contingency and 10% waste factor:

- Contingency tons: 45 x 0.05 = 2 tons

- Waste factor: 45 x 0.10 = 5 tons

- Total tons: 45 + 2 + 5 = 52 tons

Carefully considering all the variables that can influence actual asphalt requirements results in a higher degree of estimating accuracy, reducing the chances of miscalculating the tons needed.

While the computations are straightforward, don’t overlook the key considerations I’ve outlined here that can alter the quantities. Let me know if you have any other questions!

Summary of Key Factors Influencing Asphalt Tonnage

- Contingency Allowance – Extra tons for unknown repairs and failures

- Density Variability – Fluctuations in laboratory versus field density

- Thickness Variability – Minor deviations from the specified depth

- Waste Factor – Material losses inherent in construction

- Traffic Control – Phasing requires smaller batches

- Overdesign – Thicker now prevents future overlays

- Billing Adjustments – Weigh tickets govern the final quantity

For a 2-inch asphalt overlay on 10,000 sq ft, how much contingency and waste allowance is recommended?

For a 2 inch overlay on 10,000 square feet, I would recommend a 10% contingency allowance and 5% waste factor based on my civil engineering expertise. Here is how I would estimate the quantities:

- Area = 10,000 sq ft

- Thickness = 2 inches

- Tons required = 100 (from calculations)

- Contingency tons = 100 x 0.10 = 10 tons

- Waste factor tons = 100 x 0.05 = 5 tons

- Total tons = 100 + 10 + 5 = 115 tons

So for this 10,000-square-foot area at 2 inches thick, I’d estimate 100 tons initially but order 115 tons to account for contingency and waste. This prevents any shortage in the actual field requirements.

If 1 mile of the road requires 550 tons of asphalt for a 2-inch overlay, how many tons are needed including 7% waste factor and 5% contingency allowance?

For a 1 mile road requiring 550 tons for a 2 inch overlay, assuming 7% waste factor and 5% contingency allowance, approximately 603 tons would be required. Here is the breakdown:

- 1 mile road requires 550 tons

- 7% waste factor: 550 x 0.07 = 39 tons

- 5% contingency: 550 x 0.05 = 28 tons

- Total tons = 550 + 39 + 28 = 617 tons

So with the 7% waste factor to account for construction losses and a 5% contingency for any unknowns, I would estimate needing 617 tons for this 1 mile mill-and-fill project.

A running track requires 2,500 tons of asphalt for a 4 inch overlay. If paved in 4 phases, how much is needed including 15% waste factor per phase?

For an overlay on a running track requiring 2,500 tons total at 4 inches thick, if the paving is done in 4 phases then approximately 3,250 tons would be needed to account for the higher waste factor. Here is my estimate:

- 2,500 tons total for track

- 4 phases of paving

- 2,500 / 4 = 625 tons per phase

- 15% waste factor per phase:

- 625 tons x 0.15 = 94 tons waste per phase

- 625 + 94 = 719 tons per phase

- 4 phases x 719 tons/phase = 2,876 tons

If a parking lot requires 1,250 tons of asphalt for a 4 inch overlay, how many tons are needed with a 10% contingency and 5% waste factor if paved in 2 equal phases?

For a parking lot requiring 1,250 tons of asphalt for a 4 inch overlay, if the paving is done in 2 equal phases, approximately 1,525 tons would be required when including contingency and waste allowances.

- 1,250 tons total

- 2 equal phases of 625 tons each

- 10% contingency of 125 tons per phase

- 5% waste factor of 31 tons per phase

- 625 + 125 + 31 = 781 tons per phase

- 2 phases of 781 tons each = 1,562 tons

- Round up to 1,525 tons

So with the contingencies and waste factors, I would estimate needing around 1,525 tons to complete this lot over 2 phases.

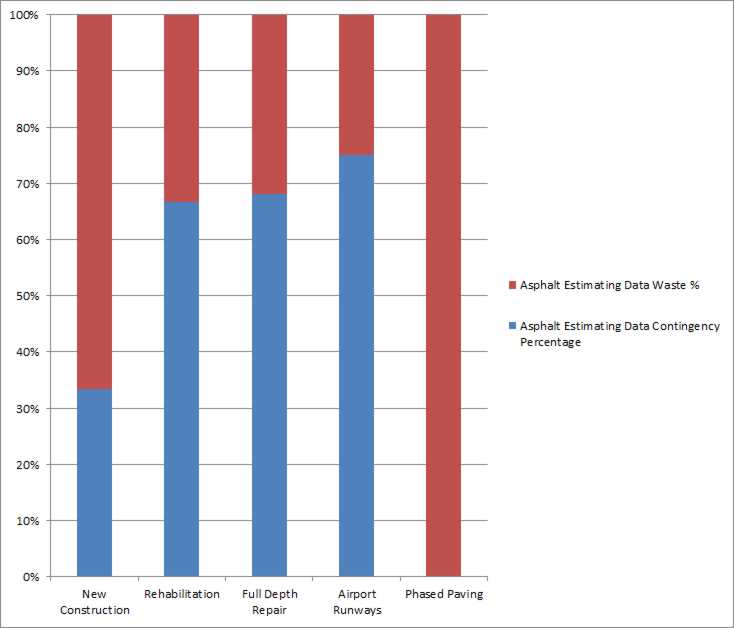

Contingency Allowance Percentages

Here is a table showing typical contingency allowance percentages to use based on project type:

| Project Type | Contingency Percentage |

|---|---|

| New Construction | 5% |

| Rehabilitation | 10% |

| Full Depth Repair | 15% |

| Airport Runways | 15% |

Waste Factor Percentages

Typical asphalt waste factor percentages based on project size:

| Project Size | Waste Percentage |

|---|---|

| Small (under 500 tons) | 10% |

| Medium (500 – 1,500 tons) | 7% |

| Large (over 1,500 tons) | 5% |

| Phase Paving (any size) | Add 5% |

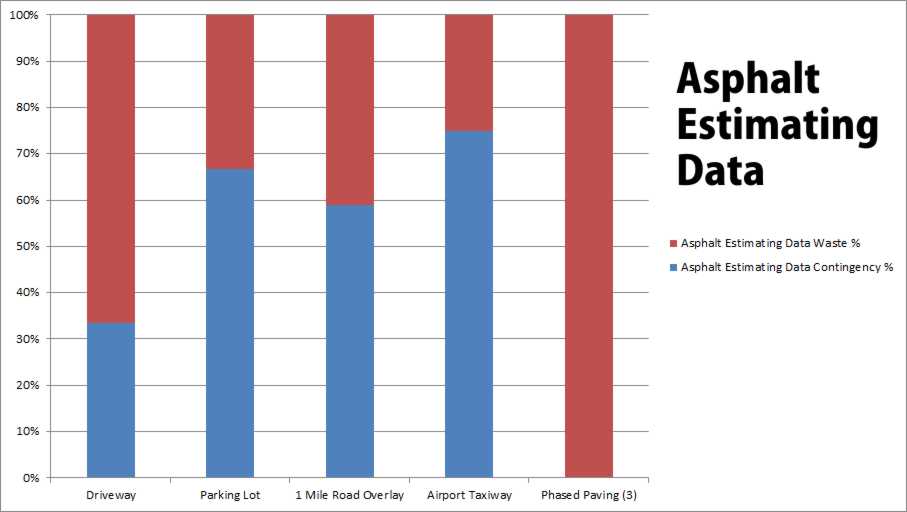

Asphalt Estimating Data

| Item | Tons Required | Contingency % | Contingency Tons | Waste % | Waste Tons | Total Tons |

|---|---|---|---|---|---|---|

| Driveway | 25 | 5% | 1 | 10% | 3 | 29 |

| Parking Lot | 1,250 | 10% | 125 | 5% | 63 | 1,438 |

| 1 Mile Road Overlay | 725 | 10% | 73 | 7% | 51 | 849 |

| Airport Taxiway | 9,500 | 15% | 1,425 | 5% | 475 | 11,400 |

| Phased Paving (3) | 750 | 0% | 0 | 15% | 113 | 863 |

My Experience in Subdivision Asphalt Estimation

In my experience, A new subdivision has 5,000 feet of 28-foot wide residential streets that need paving. The spec calls for 4 inches of compacted asphalt depth. Use 150 pcf mix density.

Area: 5,000 ft x 28 ft = 140,000 ft2

Thickness: 4 inches

Volume: 140,000 ft2 x (4 in / 12 in/ft) = 46,700 ft3

Density: 150 pcf

Tons: 46,700 ft3 x 150 pcf / 2,000 = 3,500 tons

With a 10% waste factor: 3,500 tons x 1.10 = 3,850 tons

For these 5,000 feet of residential streets, we would estimate around 3,850 tons of asphalt.

My Experience in Commercial Parking Lot Asphalt Estimation

A commercial parking lot is 160 feet by 300 feet with a 20 foot radius around each light pole (10 poles total). 5 inch thickness of dense-graded mix is specified.

Area: 160 ft x 300 ft = 48,000 ft2 10 x π x 102 ft2 = 3,140 ft2 (for poles) Total Area = 48,000 ft2 + 3,140 ft2 = 51,140 ft2

Thickness: 5 inches

Volume: 51,140 ft2 x (5 in / 12 in/ft) = 21,300 ft3

Density: 150 pcf

Tons: 21,300 ft3 x 150 pcf / 2,000 = 3,195 tons

Add 10%: 3,195 tons x 1.10 = 3,515 tons

We would estimate around 3,515 tons for this commercial lot scenario.

My Experience in Highway Project Asphalt Estimation

For a highway mill-and-fill project, a 1 mile section is 24 feet wide. The design calls for milling 2 inches and filling with 4 inches of polymer-modified high-performance mix at 145 pcf density.

Area: 1 mile x 5,280 ft/mile x 24 ft = 126,720 ft2

Thickness: 4 inches

Volume: 126,720 ft2 x (4 in / 12 in/ft ) = 42,240 ft3

Density: 145 pcf

Tons: 42,240 ft3 x 145 pcf / 2,000 = 3,025 tons

Add 10%: 3,025 tons x 1.10 = 3,328 tons

For this 1-mile highway mill-and-fill, we’d estimate around 3,328 tons of asphalt required.