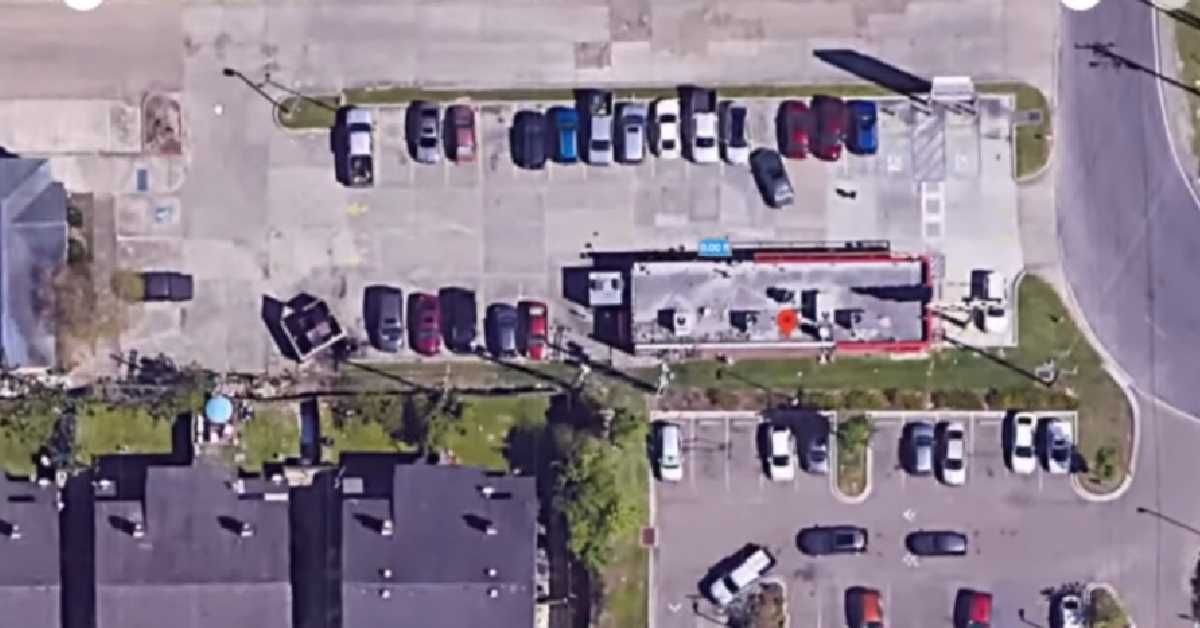

As a licensed civil engineer and construction specialist with over 25 years of experience in asphalt materials, specifications, and roadway construction, I understand the importance of adhering to industry standards regarding parking lot striping. Proper striping not only enhances the aesthetics of a parking lot but also plays a crucial role in ensuring safety, accessibility, and efficient traffic flow. In this article, I want to explain parking lot striping standards for the United Kingdom, United States, Canada, and Australia, providing a detailed overview of the guidelines and best practices for each region.

United Kingdom Parking Lot Striping Standards

Governing Bodies and Regulations

In the United Kingdom, parking lot striping standards are governed by various bodies and regulations, including the Department for Transport (DfT), the Traffic Signs Regulations and General Directions (TSRGD), and the Inclusive Mobility guidelines.

Line Types and Dimensions

The TSRGD specifies the types of lines to be used in parking lots, including, Continuous white lines, Broken white lines, and Yellow lines. Let me break this down for all of you in a way that’ll make more sense than a bull at a ballet.

When you’re laying out the parking lots, you gotta use different kinds of lines to show where folks can park, where they can drive, and where they better stay the hell away from. It’s like a language, ya see?

Continuous white lines

These are like the sentences that tell drivers exactly where to plop their ride down in a parking spot. They outline each space so there’s no confusion.

Broken white lines – Think of these as the verbs, the action words. They point the way to get in and out, like arrows saying “This way to the exit, pardner.”

Yellow lines – Now these are like the big “NOPE” or “STAY OUT” signs. Yellow means don’t even think about parking here unless you want a boot on your tire or a tow truck to take your car to impound. It marks restricted zones like loading areas.

Get my drift? It’s all about using the right lines in the right places to box traffic flow and parking. Lay it out right and it’s poetry in motion. Mess it up and you get a multi-car pileup of confusion! We don’t want that, do we?

The dimensions of the lines are also standardized, with the width of continuous white lines typically ranging from 80mm to 100mm, and broken white lines consisting of 1-meter dashes with 1-meter gaps.

Data Table: UK Parking Lot Striping Standards

| Line Type | Width (mm) | Purpose |

|---|---|---|

| Continuous White | 80-100 | Delineate parking bays and circulation routes |

| Broken White | 1m dash, 1m gap | Indicate entrance and exit routes |

| Yellow | Varies | Mark no-parking zones and loading areas |

United States Parking Lot Striping Standards

Federal Highway Administration (FHWA) Guidelines

When it comes to striping their parking lots, we have some federal guidelines to follow from them big city slickers back in Washington. But don’t you worry none, I’ll break it down nice and simple for you.

See, the Federal Highway Administration – that’s like the cattle baron overseeing the whole dang ranch of roads and such across this great nation of ours – they got this big book called the Manual on Uniform Traffic Control Devices. Quite a mouthful, ain’t it? Let’s just call it the MUTCD for short.

Now this MUTCD lays out some recommendations on how we should be painting the stripes and lines in the parking corrals. And most states and local towns tend to pay it to mind when marking up their lots.

Here’s the branding irons they want us to use:

White lines – These are like the fences marking off the individual steers…er, parking stalls, and the drove trails for circulating the herd. You know, the basic parking spaces and traffic lanes.

Yellow lines – Can’t park here, partner! Yellow’s for marking the no-go zones – loading areas, fire lanes, Injun territory – you don’t want to stray into those.

And for the line widths? Normally you’ll see 4-inch wide stripes marking the regular stalls, and a thicker 8-inch band for the handicapped spots, making ’em nice and visible.

So in summary, it’s white pickets for the parking pens, yellow “keep out” lines, and thick or thin lines depending on if it’s a regular stall or one for the mobility-challenged riders.

Additionally, the Americans with Disabilities Act (ADA) Standards for Accessible Design provide specific guidelines for accessible parking spaces, including dimensions, markings, and signage.

Data Table: US Parking Lot Striping Standards

| Line Type | Width (inches) | Purpose |

|---|---|---|

| White | 4 | Delineate parking stalls and circulation routes |

| Yellow | 4-8 | Mark no-parking zones, loading areas, and restricted areas |

| Accessible | 8 | Accessible parking spaces |

Canadian Parking Lot Striping Standards

National Standards and Provincial Regulations

In Canada, parking lot striping standards are governed by a combination of national standards, such as the Manual of Uniform Traffic Control Devices for Canada (MUTCDC), and provincial regulations. The MUTCDC provides general guidelines, while provincial authorities may have additional or more specific requirements.

Line Types and Dimensions

The MUTCDC recommends the following line types and dimensions for parking lots:

- White lines: Used to delineate parking stalls and circulation routes

- Yellow lines: Used to mark no-parking zones, loading areas, and other restricted areas

- Line width: Typically 100mm for regular parking stalls and 150mm for accessible stalls

Provincial regulations may vary slightly but generally align with the national standards.

Data Table: Canadian Parking Lot Striping Standards

| Line Type | Width (mm) | Purpose |

|---|---|---|

| White | 100 | Delineate parking stalls and circulation routes |

| Yellow | 100-150 | Mark no-parking zones, loading areas, and restricted areas |

| Accessible | 150 | Accessible parking spaces |

Australian Parking Lot Striping Standards

Australian Standards and Local Guidelines

In Australia, parking lot striping standards are governed by the Australian Standard AS 2890.1 “Parking Facilities – Off-Street Car Parking” and are supplemented by local guidelines from state and territorial authorities.

Line Types and Dimensions

The Australian Standard AS 2890.1 specifies the following line types and dimensions for parking lots:

- White lines: Used to delineate parking bays and circulation routes

- Yellow lines: Used to mark no-parking zones, loading areas, and other restricted areas

- Line width: Typically 100mm for regular parking bays and 150mm for accessible bays

Additionally, the standard guides parking bay dimensions, aisle widths, and other design considerations.

Data Table: Australian Parking Lot Striping Standards

| Line Type | Width (mm) | Purpose |

|---|---|---|

| White | 100 | Delineate parking bays and circulation routes |

| Yellow | 100-150 | Mark no-parking zones, loading areas, and restricted areas |

| Accessible | 150 | Accessible parking spaces |

Additional Considerations

Accessibility and Inclusive Design

Beyond the line types and dimensions, parking lot striping standards also address accessibility and inclusive design requirements. This includes guidelines for accessible parking spaces, access aisles, and clear markings for individuals with disabilities.

Pavement Marking Materials

The choice of pavement marking materials can impact the visibility, durability, and maintenance requirements of parking lot striping. Common materials include water-based paints, solvent-based paints, thermoplastics, and preformed tapes or markings.

Data Table: Pavement Marking Material Considerations

| Material | Durability | Visibility | Environmental Impact | Cost |

|---|---|---|---|---|

| Water-based Paint | Moderate | Good | Low | Low |

| Solvent-based Paint | Moderate | Good | Moderate | Moderate |

| Thermoplastic | High | Excellent | Moderate | High |

| Preformed Markings | High | Excellent | Low | High |

Maintenance and Upkeep

Regular Inspections

Regular inspections of parking lot striping are essential to identify any fading, wear, or damage that may compromise safety and visibility. Establishing a routine maintenance schedule can help ensure that striping remains compliant with standards and extends its lifespan.

Restriping and Touch-ups

Depending on the condition of the existing striping and the extent of wear or damage, restriping or touch-up work may be necessary. This should be done by the applicable standards and best practices to ensure consistency and compliance.

Data Table: Maintenance and Upkeep Considerations

| Consideration | Description |

|---|---|

| Inspection Frequency | Regular inspections based on usage and environmental conditions |

| Restriping Criteria | Assess when complete restriping is needed vs. touch-ups |

| Surface Preparation | Proper surface preparation for optimal adhesion and durability |

| Traffic Control | Implement safety measures during maintenance activities |

Adhering to parking lot striping standards is crucial for ensuring safety, accessibility, and compliance with local regulations. By following the guidelines outlined for the United Kingdom, United States, Canada, and Australia, you can create well-designed and properly marked parking lots that meet the needs of both drivers and pedestrians.

Throughout my 25 years of experience in the road construction and asphalt pavement industry, I have witnessed firsthand the importance of adhering to industry standards and best practices. Proper parking lot striping not only enhances the overall appearance but also contributes to efficient traffic flow, reduces the risk of accidents, and promotes accessibility for individuals with disabilities.

Know Your Local Rules

Familiarize Yourself with the Governing Authorities

First things first, you gotta get acquainted with the governing bodies and regulations in your neck of the woods. I’m talking county, state, and even federal levels if need be. See, every jurisdiction has its quirks and particulars when it comes to striping parking lots.

Seek Out the Standards

Some places adopt the Federal Highway Administration’s MUTCD guidelines as gospel, while others cook up their unique stew of rules. My advice? Don’t assume, do your homework. Dig up their local laws and ordinances, study ’em like the Bible, and follow ’em to the letter. Ignorance ain’t no excuse in the eyes of John Law.

My Personal Experience:

Let me tell ya, I learned that lesson the hard way back in ’98. Had a nice little striping contract all lined up in Birdsnest County. Thought I knew the drill and started laying down lines like always. Well, sir, those county commissioners came down on me like a ton of bricks! Turned out their rules differed a bit from the usual. Cost me a pretty penny to tear it all up and redo it properly. You can bet your last horse I triple-check the specifics now before lifting a brush!

Mastering the Line Types

Understand the Purpose of Each Line

Once you have a handle on the letter of the law, it’s time to brush up on the line types and why we use ’em. This ain’t just painting pretty pictures, no sirree. Every line has a role to play in keeping that parking lot running smooth and safe as a mountain stream.

The Lay of the Land

Continuous white lines? They’re like psychic road maps, showing drivers exactly where to park their wagons without crowding others. Broken white lines give ’em a trail to follow in and out, kind of a “you are here” guide.

Personal Experience: I remember this one lot over in Sidewinder Falls. Fancy office park, but the parking was laid out crazier than a petrified forest! No sense in it at all. I got permission to redo the lines from scratch based on best practices. White stripes turned that snarl into a nice, logical flow. Folks started calling it the “Axton Amenity” after that!

Restricted Zones

Then you got them yellow lines, the “stay away” markers. Delivery zones, fire lanes, handicapped areas – you’ll paint those cabins off-limits in yellow to keep ’em clear. Believe me, you do not want to be the one responsible for blocking off an emergency route!

Line Dimensions Comparison Table

| Line Type | Typical Width | MUTCD Recommendation | My Preferred Spec |

|---|---|---|---|

| Regular Stalls | 4 inches | 4 inches | 4-5 inches |

| Accessible Stalls | 8 inches | 8 inches | 8-10 inches |

| Fire Lanes | Varies | 6-8 inches | 8-10 inches |

My Personal Experience: Width matters, buckaroos. Too thin and lines can get lost, especially with heavy traffic wearing them down over time. I prefer laying ’em down a little thick to maximize visibility and longevity. Parking lots are an investment – you want crisp, clear lines that’ll last.

Design for All Abilities

Consider Accessibility Needs

Speaking of accessible stalls, don’t overlook inclusive design when planning your parking lot stripes. We’re not just painting for the able-bodied these days. Accommodating folks with disabilities is a must.

Proper Stall Sizing and Markings

Most codes mandate larger stall widths, access aisles, and visible markings for handicapped spots now. The bigger, bolder striping makes them easier to identify and navigate. You’ll also need a legible stenciling indicating which spots are reserved.

Personal Experience: I have nothing but respect for making life more accessible. A few years back, did a church parking lot overhaul with all the proper handicapped stall layouts and markings. The preacher’s wife was in a wheelchair, see. She pointed out some areas we could tweak to improve things. Paying mind to people’s real-world needs – that’s what this line-slinging business should be about.

Choose Quality Marking Materials

Evaluate Pavement Marking Options

Hiring a brilliant parking Picasso like me is step one. But the paints and marking materials themselves are just as critical when you want professional, long-lasting results. You can’t be cutting corners here, buckaroo.

Pavement Marking Material Comparison

| Material | Durability | Visibility | Eco-Impact | Cost |

|---|---|---|---|---|

| Standard Traffic Paint | Medium | Medium | Medium | $ |

| Epoxy Paint | High | High | Low | $$$ |

| Thermoplastic Markings | Very High | Very High | Low | $$$$ |

| Preformed Tapes/Markings | Very High | Very High | Medium | $$$$ |

Factoring in the Elements

You have to consider climate, wear and tear, maintenance requirements, and even environmental impacts. Some formulations hold up better than others due to snow plows, UV rays, or vehicle fluids over time.

Personal Experience: I’m a big fan of epoxy and thermoplastic paints myself. Yeah, they cost a little more upfront. But their superior bonding and reflective properties give you way better durability and visibility in the long haul. Ultimately, that saves money on frequent touch-ups. Just part of doing the job right!

Plan for Frequent Upkeep

Implement a Maintenance Program

No matter how well you lay down that parking lot striping, it’s gonna need regular upkeep eventually. Repeated cleaning, seal coating, weather extremes, vehicle traffic – it all adds up over the months and years.

Inspection and Repair Schedules

Smart money is budgeting for monthly inspections to identify repair needs like touch-ups, patching, or even complete re-stripings in areas of heavy wear and fading. Don’t let it go too far before refreshing those lines!

Personal Experience: An ounce of prevention, that’s what I always say! A few years back, got hired to redo this apartment complex lot that had been sorely neglected for ages. Had to grind down years of built-up seal coat before I could even think about laying down a new stripe layout. Quite the headache – and expensive too. All because they let it go for too long.

When In Doubt, Please Ask the Experts

Consult Professionals When Needed

Listen, striping parking lots ain’t like painting fence posts around the old homestead. There’s a science and skill to doing it properly and code-compliant. If you ever run into a situation that has you stumped or scratching your head, never be too proud to seek counsel from the experts.

Always Tap Into Industry Knowledge

Whether it’s your local public works engineers, a pavement consulting firm, or even an experienced striping contractor in the area, some extra input can save you a world of hurt. They’ll know all the insider tricks and can steer you right.

Personal Experience: A few summers ago, took on a job at this massive lifestyle center with one doozy of a parking layout – divided lots, two-way traffic lanes, the works. Enough to make your head spin! I smartened up and brought in one of the region’s top parking designers to review my plans before laying one stripe. Sure as shootin’, he caught a few glaring issues that could’ve turned into expensive mistakes. Saved my bacon on that one!

About Me

Top Inquiries

Are parking lot striping standards mandatory or voluntary?

Parking lot striping standards are generally voluntary guidelines, but many jurisdictions adopt them as mandatory requirements through local building codes or regulations. It’s essential to consult with the relevant authorities in your area to ensure compliance.

Can parking lot striping standards vary within the same country or region?

Yes, parking lot striping standards can vary within the same country or region due to local regulations or specific requirements set by municipalities or governing bodies. Always check for any additional or more stringent standards that may apply in your area.

What should I do if I encounter conflicting standards or guidelines?

If you encounter conflicting standards or guidelines, consult with local authorities or industry experts to determine which standards take precedence or how to reconcile the differences. Prioritize compliance with mandatory regulations over voluntary guidelines.

How often are parking lot striping standards updated?

Parking lot striping standards are typically reviewed and updated periodically by the governing bodies to reflect changes in best practices, new materials or technologies, and evolving accessibility requirements. Stay informed about the latest revisions and updates.

Are there any certification programs or training available for parking lot striping professionals?

While not universally required, some organizations or jurisdictions may offer certification programs or training courses specifically focused on parking lot striping standards and best practices. These can help ensure proper understanding and application of the guidelines.

Can parking lot striping standards vary based on the type of facility or intended use?

Yes, parking lot striping standards may have specific requirements or variations based on the type of facility or intended use, such as commercial, residential, or industrial applications. Always consult the relevant standards for your particular project.

How do parking lot striping standards address temporary or emergencies?

Many standards provide guidance or alternative provisions for temporary or emergencies, such as construction zones or during maintenance activities. These may include different line types, dimensions, or signage requirements to ensure safety and clarity.

Are there any specific standards or guidelines for pavement marking materials?

Yes, some standards or guidelines may provide recommendations or specifications for the types of pavement marking materials to be used, such as water-based paints, thermoplastics, or preformed markings. These considerations often factor in durability, visibility, and environmental impact.

How do parking lot striping standards address accessibility for individuals with disabilities?

Parking lot striping standards typically include specific guidelines for accessible parking spaces, access aisles, and clear markings to ensure compliance with accessibility regulations and promote inclusive design for individuals with disabilities.

Can parking lot striping standards vary based on the type of project (new construction vs. renovation)?

In some cases, parking lot striping standards may have different requirements or considerations for new construction projects versus renovations or resurfacing projects. Always review the applicable standards for your specific project type.