[labor_cost_calculator]

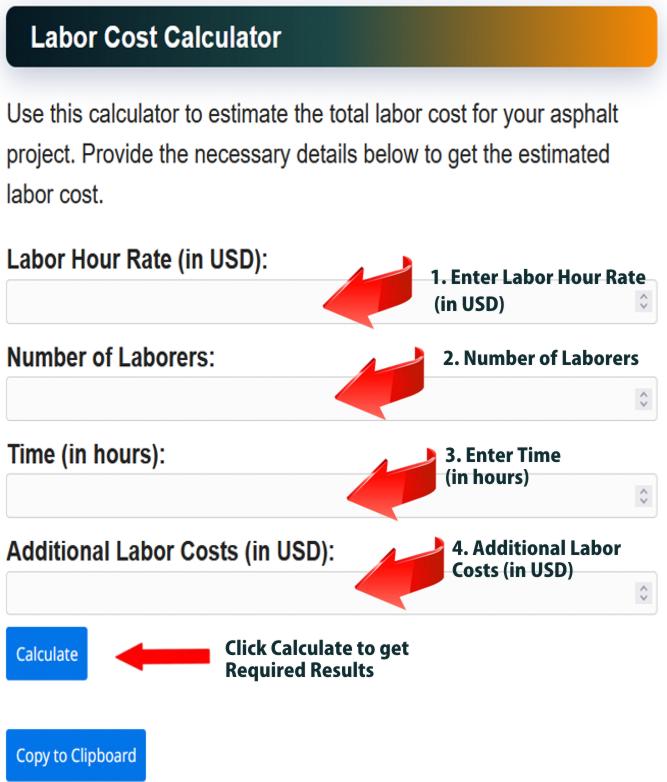

- Input the labor hour rate, number of laborers, time in hours, and additional labor costs to calculate the total labor cost for an asphalt project.

- The total labor cost is calculated using the formula:

Total Labor Cost=(Labor Hour Rate×Number of Laborers×Time)+Additional Labor Costs

How to use Labor Cost Calculator

How to Accurately Calculate Your Labor Costs in 5 Steps

Figuring out true labor costs is essential for every road construction business, but the calculations can quickly get complex. This guide will walk you through a simple 5-step process to calculate direct and indirect labor costs accurately.

At its essence, labor costs encapsulate the financial outlay a business incurs in compensating its workforce. It’s not just about the basic salaries; it also encompasses the entire spectrum of monetary remuneration, including overtime wages, bonuses, and benefits such as healthcare and retirement plans.

First, we will learn how to calculate labor cost heads in Road construction projects. Learn how to factor in hourly wages, overhead costs, and hours worked to get a precise handle on total labor expenditures.

Why Understanding Your Labor Costs Matters

Knowing exactly what your labor costs entails many benefits:

- Price products/services correctly by including accurate labor cost portions.

- Get the labor cost percentage with the hourly rate, this will ensure to adjust work hours in the business.

- Make data-driven decisions on ways to improve productivity and lower labor costs.

- Set realistic budgets around projects and operations needing human capital.

- Optimize resource allocation between automation and human work efficiently.

- Identify high labor cost areas needing improvement.

Accurately calculating labor costs gives you crucial insights into one of the largest expenses for every business.

Understand Cost Calculation in Road Projects

Road construction cost estimation is a critical aspect of project planning and budgeting. Factors such as surveying, clearing, excavation, surfacing, and drainage play a significant role in determining construction costs. Accurate estimation requires a deep understanding of production rates, machine rates, and other variables. Different construction activities have their own unique cost considerations. Balancing equipment and production rates is essential for cost-effective road construction as well.

Prior to examining the complexities of estimating road construction costs, it’s crucial to understand the basic principles. Here are the important details you should be aware of:

1. Understanding the Components:

Road construction costs are the sum of various subunit costs, including surveying, clearing, excavation, surfacing, and drainage.

2. Factors Affecting Surveying:

Surveying costs vary based on job size, terrain, and location. Estimating production involves calculating the number of stakes set per hour.

3. Clearing and Piling:

Clearing and piling costs depend on factors like right-of-way size and tree removal. Different methods are used for clearing, including mechanized techniques.

4. Mechanized Clearing:

For mechanized clearing, factors like hardwood density, vine density, and tree size play a role in estimating production rates.

5. Mechanized Piling:

Mechanized piling rates consider factors such as tree diameter and tree density.

Road Construction Unit Costs

Road construction unit costs are a fundamental aspect of any infrastructure project. They provide the basis for estimating the overall cost and budgeting effectively. In this section, we will delve into the components that comprise road construction unit costs and the pivotal roles played by machine rates and production rates.

What Comprises Road Construction Unit Costs?

To grasp the concept of road construction unit costs, it’s essential to break down the various components that contribute to these costs. Here’s an overview:

- Surveying Costs: Surveying plays a critical role in road construction, and the expenses associated with surveying activities are part of the unit costs.

- Clearing and Grubbing Costs: Clearing land and removing vegetation are essential preparatory steps, and these costs are factored into unit costs.

- Excavation Costs: The process of excavating earth or rock to prepare the roadbed is a significant cost element.

- Surfacing Costs: The choice of surfacing material, its quantity, and transportation expenses are all part of the unit costs.

- Drainage Costs: Road drainage systems, including culverts and drainage ditches, contribute to the overall unit costs.

- Earthwork Costs: Moving and shaping earth materials to create the road’s foundation are integral to unit costs.

- Finish Grading Costs: Achieving the desired grade for the road’s substructure involves costs related to grading equipment and labor.

- Additional Costs: Other factors like labor, equipment maintenance, fuel, and project-specific expenses are also considered.

1. The Role of Machine Rates and Production Rates

Machine rates and production rates are two key factors that influence road construction unit costs:

- Machine Rates: Machine rates refer to the cost associated with operating construction equipment. This includes expenses like fuel, maintenance, operator wages, and depreciation. Accurate machine rate calculations are essential for estimating unit costs.

- Production Rates: Production rates indicate the efficiency of various construction activities. They are typically measured in terms of work completed per unit of time (e.g., cubic meters per hour or kilometers per hour). Production rates are crucial for estimating the time required for specific tasks and, consequently, their associated costs.

Understanding how these factors interact and impact road construction unit costs is essential for project planning and budgeting.

2. Surveying: Estimating Costs and Efficiency

Surveying is a critical phase in road construction, laying the foundation for accurate planning and execution. In this section, we’ll explore the factors that affect surveying costs and delve into the calculations of surveying production rates.

Factors Affecting Surveying Costs

Surveying costs can vary significantly based on various factors, including:

- Job Complexity: The intricacy of the project, terrain, and environmental conditions can impact surveying costs.

- Job Size: Larger road construction projects may have economies of scale, reducing surveying costs per kilometer.

- Terrain and Accessibility: Rugged terrain or challenging accessibility can increase surveying expenses.

- Surveying Method: The choice between traditional land surveying and modern surveying technologies like LiDAR or GPS can affect costs.

- Crew Experience: The efficiency and expertise of the surveying crew can influence costs.

Calculating Surveying Production Rates

Efficient surveying of production rates is crucial for estimating costs accurately. Here’s how surveying production rates are calculated:

Example: Suppose a survey crew sets 300 stakes per kilometer at a rate of 15 stakes per hour, with the cost of the survey crew, including transport, at $10 per hour.

- Production Rate (P) = Stakes set per hour / Stakes required per kilometer

- P = 15 / 300 = 0.05 km/hr

- Unit Cost (UC) = Cost per hour / Production Rate

- UC = $10 / 0.05 = $200/km

Efficient surveying ensures that road construction proceeds with precision, minimizing errors and potential delays.

3. Cost Factors and Methods In Clearing and Piling:

Clearing and piling are pivotal phases in road construction, setting the stage for a sturdy roadbed. This section delves into understanding the intricacies of clearing and piling costs and the efficiency of mechanized techniques.

Understanding Clearing and Piling Costs

Clearing and piling costs are influenced by several key factors:

- Land Area: The total land area earmarked for clearing and piling per kilometer significantly impacts overall costs.

- Terrain Complexity: The geographical intricacies, including rugged terrain, dense vegetation, or rocky sections, can escalate clearing and piling expenses.

- Methodology: The choice between manual and mechanized methods plays a significant role in determining costs. Mechanization often proves cost-effective, especially in extensive projects.

- Stump Removal: If the project necessitates the removal of tree stumps, this adds an additional layer of cost.

Mechanized Clearing and Piling Techniques

Mechanized methods have revolutionized clearing and piling processes, enhancing efficiency and cost-effectiveness. Here’s a closer look at mechanized techniques:

- Clearing Time (Tc): Mechanized clearing time depends on multiple factors, such as tree size and density. The formula for calculating Tc is:Tc = (X/60) (AB + M1N1 + M2N2 + M3N3 + M4N4 + DF)Where X is the hardwood density factor, A is the vine density factor, B is the base minutes per hectare, M represents the minutes per tree in each diameter range, N signifies the number of trees per hectare in each diameter range, D is the sum of diameters of all trees per hectare larger than 180 cm, and F denotes the minutes per centimeter of diameter to cut trees with diameters greater than 180 cm.

- Piling Time (Tp): When using a rake or angled shearing blade for piling, Tp can be calculated with the following formula:Tp = (1/60) (B + M1N1 + M2N2 + M3N3 + M4N4 + DF)Similar to clearing, the variables denote factors such as tree size, density, and diameter.

Mechanized clearing and piling can significantly enhance productivity and precision. Additionally, these methods are well-suited for handling challenging terrain and large-scale projects.

By grasping the intricacies of clearing and piling costs and embracing mechanized techniques, road construction endeavors can efficiently prepare the groundwork for a successful project.

4. Estimating Earthwork Costs

The cost associated with earthwork hinges on the volume of soil and rock that must be excavated and relocated to craft the road. To arrive at these estimates, engineers employ formulas and tables that factor in the dimensions of the road, side slopes, cut and fill ratios, and road width. Additionally, the type of equipment used is integral to estimating costs. Production rates for bulldozers and hydraulic excavators play a pivotal role in cost estimations.

For instance, an area with a 6.0-meter subgrade on a 30 percent slope, employing a 1.5:1 fill slope and 0.5:1 cut slope, accompanied by a one-foot ditch and a 20 percent shrinkage factor, would amount to approximately 2100 bank cubic meters per kilometer for a balanced section.

Determining an average production rate for common material, devoid of rock, is critical. For instance, an equipment performance handbook might specify a rate of 150 bank cubic meters per hour for a 300-hp power-shift tractor with a ripper attachment, with a corresponding cost of $80 per hour. Calculating the rate of excavation follows this equation:

P = (150 m3/hr)/(2100 m3/km) = 0.07 km/hr

This rate, when used to estimate unit costs, results in:

UC = 80/0.07 = $1143/km

In cases where earthwork isn’t placed or sidecast within a proximity of 50 meters from the excavation site, additional costs associated with pushing the material to the placement location must be considered. Scrapers excavators and dump trucks can be employed for this task.

Excavation rates in rocky terrain, on the other hand, depend on factors such as job size, rock hardness, and local conditions. Blasting is often an integral component of rock excavation, and estimates of blasting production rely on equipment size and the specific job at hand.

For example, a 10 cm track-mounted drill and a 25 cubic meter per minute air compressor can prepare 40 cubic meters per hour for small, shallow blasts and 140 cubic meters per hour for more extensive, deeper blasts, including quarry development to produce rock surfacing. Costs in such cases can include expenses for explosives, typically around $2 per kilogram.

Factors Influencing Earthwork Production Rates

Earthwork production rates can be influenced by a multitude of factors, including but not limited to:

- Job Size: The scale and magnitude of the earthwork project significantly affect production rates. Larger projects often yield economies of scale.

- Soil Composition: The type of soil or rock being excavated plays a role. Harder materials may slow down excavation rates.

- Equipment Selection: The choice of excavation machinery, including its size and efficiency, is crucial in determining production rates.

- Local Conditions: Regional variables such as weather, terrain, and accessibility can have a substantial impact on earthwork productivity.

Comprehending the subtleties of calculating earthwork expenses and identifying elements that affect production rates enables meticulous planning and implementation of road construction projects, ensuring they are cost-efficient and productive.

So, Here is the step-by-step guide to calculating labor costs.

Step 1 – Determine Hourly Wage Rates

The first step is calculating the hourly wage rates for different employee categories:

- For salaried employees, divide the annual salary by the total number of hours worked in a year (around 2,080 hours).

- Hourly employees already have a set hourly wage rate.

- Include any bonuses or incentives that substantially supplement base pay.

Tabulating regular and overtime wage rates by department provides a clear picture of labor cost by hour. You will be able to know how much an employee costs.

Step 2 – Account For Overhead Costs

Next, factor in overhead costs by adding:

- Employment taxes – Social Security, Medicare, federal and state taxes.

- Benefits – health insurance, retirement plans, tuition reimbursement, etc.

- Training and recruitment costs.

- Safety gear, uniforms, and other expenses.

- Technology, equipment, and tools for workers.

Overhead costs can range from 20% to over 50% of base pay. Tracking these accurately is key.

Step 3 – Calculate Billable Hours

To get billable hours:

- Hourly employees: Take total hours worked minus breaks, sick days, holidays, etc. The hourly labor cost formula is based on number of hours.

- For example, let’s say an employee earns $15 per hour and works 40 hours per week. The employee’s hourly labor cost would be calculated as follows:Hourly labor cost = ($15 per hour x 40 hours per week) / 40 hours per week = $15 per hour

- Salaried: Calculate hours devoted to billable/revenue-generating tasks only, excluding administrative work.

- Part-time: Add hours across all active part-time staff.

The above three will help you to calculate direct labor cost and total labor cost.

Tabulating billable hours helps determine true labor usage and productivity.

Step 4 – Determine Indirect Labor Costs

Beyond direct production costs, indirect costs include:

- Production support activities – procurement, inventory, scheduling, logistics.

- Facilities – rent, utilities, property tax, maintenance.

- Equipment repair and maintenance.

- Management and administration.

Analyzing indirect costs reveals overhead efficiency and opportunities to streamline.

Step 5 – Calculate Total Costs

Finally, add up:

- Direct wage rates x billable hours

- Overhead costs

- Indirect labor costs

The total provides your complete labor expenditure. Comparing it against past periods indicates trends and areas needing improvement.

How to Use Labor Cost Information

Accurate labor data helps:

- Set competitive pricing – Include realistic labor cost portions in product/service pricing.

- Reduce labor costs – Analyze results to find ways to cut unproductive hours and overhead waste.

- Forecast budgets – Labor projections become more data-driven using historical costs.

- Assess automation benefits – Compare automation costs versus labor savings to make the optimal choice.

- Monitor productivity – Establish labor cost baselines to measure against for continuous improvement.

Better understanding your true labor costs is key to making informed business decisions in multiple areas.

Strategies to Reduce Labor Costs

Effectively managing your labor costs can lead to improved profitability and sustainability for your business. Here are some strategies to help you reduce labor costs without compromising quality or employee well-being:

- Optimize Scheduling: Use historical data and forecasting tools to create efficient employee schedules that align with customer demand.

- Automation: Invest in technology and automation solutions that can streamline repetitive tasks, reducing the need for manual labor.

- Outsourcing: Consider outsourcing non-core functions to reduce the burden on your in-house workforce.

- Cross-Training: Cross-train employees to perform multiple roles, allowing you to be more flexible with staffing.

- Performance Monitoring: Regularly assess employee performance and provide feedback to encourage productivity improvements.

- Employee Benefits Review: Evaluate your employee benefits packages to ensure they are competitive but not overly generous.

Tools to Simplify Labor Cost Calculation

Specialized tools like labor cost calculators help by:

- Storing wage rates and overhead information.

- Automatically computing billable hours from inputs.

- Providing key cost metrics through intuitive dashboards.

- Generating custom reports showing labor cost breakdowns.

SaaS solutions eliminate manual calculations, save time, and provide robust analysis capabilities.

Key Takeaways on Labor Cost Computation

- Know your true labor costs by calculating precise hourly direct wage rates based on net hours worked.

- Account for all overhead costs to allocate labor fully.

- Focus on billable hours aligned with revenue goals, minimizing unproductive time.

- Combine direct wage costs, overheads, and indirect labor to derive total costs.

- Use accurate labor data for pricing, budgets, automation decisions, and productivity assessments.

What is a good percentage of labor cost?

Labor cost percentage is a crucial metric for any business and has a direct impact on the profitability of the company. However, not every company will face the same percentage of labor cost, as it greatly depends on the nature of the business, labor market conditions, and various other factors.

Businesses with a higher manual labor requirement, such as manufacturing or construction, typically have higher labor costs. Also, businesses located in areas with higher living standards or minimum wage laws will inherently have a higher labor cost.

Despite these varying factors, many experts suggest that a good labor cost percentage should be around 20-30% of the gross revenue for most businesses. In the service industry, this can go up to 50% due to the intense labor requirement. It is crucial to remember that this is not a rule set in stone but more of a generalized guideline that can help businesses manage their labor costs effectively.

If a business’s labor cost percentage is significantly higher than these guidelines, it could indicate inefficiencies within the workforce or that the price of the business’s product or service is too low.

Ultimately, having a good percentage of labor cost is about balance. Businesses need to balance the cost of labor with other operating expenses while ensuring profitability and providing a fair wage to their employees. Therefore, continuous monitoring and regular adjustments are necessary to maintain this balance.

The Core

Calculating labor costs across direct wages, overheads, billable hours, and indirect activities provides actionable data to boost competitiveness. Using an intuitive step-by-step process and specialized tools simplifies the computation. Accurate labor cost information uncovers savings opportunities and guides critical business decisions. Monitor it closely as a key metric!