Asphalt is a vital component of transportation infrastructure, providing smooth, safe surfaces for traveling. Yet weather, traffic, and age degrade even sturdy asphalt roads over time. Cracks form, potholes emerge, and without intervention, conditions worsen. Thankfully, strategic preventative maintenance preserves asphalt integrity, extends pavement life, and saves taxpayer money. Let’s explore common techniques for protected pavements.

Evaluating Pavement Condition Before treatment selection, pavement condition indexes gauge repair needs through visual surveys and tools measuring:

Surface Defects

Cracking

- Over 50% of roads have cracking within 10 years

- Fatigue cracks signal structural deficiency

- Thermal cracks from temperature fluctuations

Raveling

- Asphalt wearing away exposes the aggregate

- Caused by poor construction or binder hardening

Rutting

- Channel-worn wheels form depressions

- Reduces water runoff and causes hydroplaning

Structural Integrity

Deflection Testing

- Non-destructive evaluation of layer strength

- Falling Weight Deflectometer impacts the surface

- Sensors measure deformation for analysis

Coring

- Extracts sample plugs at various depths

- Lab tests composition, density, moisture

Picking the Right Fix Armed with knowledge of the pavement’s condition, owners can select the most effective and affordable treatment.

Minor Repairs

Crack Sealing

- Clean and fill cracks under 1⁄4 inch

- Prevents water intrusion into the structure

Crack Sealing Step 1

Crack Sealing Step 2

Pothole Patching

- Square off the hole and compact a new hot mix

- Quickly restores surface integrity

Preventative Maintenance

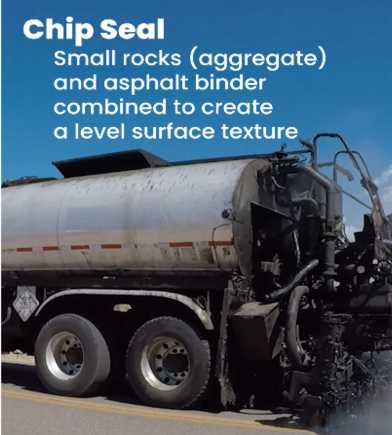

Chip Seal

- Single layer of asphalt and embedded aggregate

- Cost-effective resurfacing for low-traffic roads

Microsurfacing

- Thin polymer-modified cold mix overlay

- Ideal for weathered surfaces with minor rutting

Structural Enhancements

Mill & Overlay

- Removes 1-2 inches, replaces with 1.5-3 inches hot mix

- Significant smoothening and strengthening

Full Depth Reclamation

- Pulverizes full flexible pavement structure

- Mixes granular base with stabilizing agent

- Creates new subgrade for fresh hot mix overlay

Following rigorous evaluation procedures and strategic maintenance solutions, owners can ensure pavement preservation for the long run – keeping roads smooth, and safe, and avoiding higher rehabilitation costs down the road.

My Experiences Maintaining My Driveway Over the Years

As both a civil engineer, construction manager, and homeowner, I’ve tried practically every pavement sealer, crack filler, patch mix, and plowing technique in the book on my asphalt driveway over the past 25 years. I’ve kept meticulous notes comparing durability, ease of application, cost, and longevity across different products and approaches. Nothing gives you hands-on experience faster than experimenting in your backyard often the hard way through trial and error!

Based on resurfacing my 650 sq ft, moderately-sloped driveway in central Virginia four times now, my ratings are:

Crack Fillers

- Gardner Asphalt Crack Filler: 4.5/5 stars – superb bonding and flexibility at a reasonable price

- Latexite Rubberized Asphalt Crack Sealer: 3.5/5 stars – durable fill but dries too quickly limiting work time

- Basic emulsion filler: 2/5 stars – shrinks and crumbles readily with temperature changes

Asphalt Patch Mixes

- Quikrete Commercial Grade Patch Mix: 5/5 stars – smooth consistency, excellent adhesion, cures quick

- Standard cold patch bags: 2.5/5 stars – tends to ravel at edges as the oils separate

Asphalt Sealcoat Products

- Refined tar emulsion solutions: 4.5/5 stars – less prone to tire scuffing/tracking than cheaper grades

- Cutback asphalt sealers: 2/5 stars – never seem to adequately rejuvenate the oxidized surface

In terms of rejuvenating seal coat application, I could easily get away with a minor patch job followed by a refresh coating every 2-3 years in my climate. However, I prefer to do a full 1.5″ overlay resurfacing every 4-5 years as preventative maintenance. The deeper lift lets me smooth out minor depressions or banding since my driveway naturally wants to settle near the garage.

What I Learned From My Wet Basement Debacle

Back in 2023, I decided to try repaving a wet area at the bottom of my driveway near the house foundation instead of repeatedly re-patching it. Foolishly, I didn’t take the time to diagnose and address the underlying moisture infiltration issue first. While the new pavement looked gorgeous initially, within two months I started spotting cracks. Fast forward 60 days, and the whole section was fractured beyond repair from the freezing pressure exerted on the saturated base underneath each winter.

I had to not only tear up and rebuild that portion properly but also install drainage pipes, gravel, and a vapor barrier to keep the base layers dry ever since. That painful lesson on sequencing driveway repairs correctly so ingrained the “drainage before pavement” mantra in my thinking that I now give public presentations to industry groups on the topic!

Pros and Cons: Concrete vs Asphalt Driveways

Having replaced countless residential driveways over my career, I have strong opinions on concrete vs asphalt in home applications. Based on factors like upfront cost, durability, tear-out/replacement difficulty, and plowing/traction needs, my ratings are:

Asphalt Driveways

Pros:

- Lower upfront cost by ~15-30% [$7-12 per sq ft]

- Easier to patch small damaged areas

- Smoother vehicle ride quality

- Better grip and snow-plowing traction

Cons:

- Shorter lifespan with seals (10-25 years)

- Needs more regular sealing maintenance

- Not as durable for extremely heavy vehicles

- Vulnerable to gas & oil spills

Concrete Driveways Pros:

- Extremely durable surface (30+ years lifespans)

- Withstands heavy vehicle traffic better

- Less maintenance required

- Resists weathering and chemical spills

Cons

- More expensive initially [$8-15 per sq ft]

- Noisy ride quality as tires slap concrete

- Snow plow blades could scrape the surface over time if unsealed

- Full repairs mean replacing concrete panels

For my situation given Virginia’s winter weather, I’ve valued the extra traction of an asphalt driveway and find the maintenance tradeoff acceptable. However, for secondary driveways used less often or in warmer climates, concrete may prove the superior choice.

Key Statistics on Effective Pavement Preservation Approaches

- Applying preventative seal coats every 3-5 years extends asphalt pavement life by 4-6 years on average

- Catching & repairing cracks under 1/4 inch wide can prevent full pavement failures needing rehabilitation

- Average asphalt overlay or reconstruction costs $3-7 per sq ft versus under $0.25 per sq ft for crack sealing

- Rutting lanes or potholes over 1 inch deep indicate repaving needs on a pavement near the end of its design life

- Applying rejuvenator sealers can extend aged asphalt life by 5-8 more years

Best Machinery Used in Asphalt Preservation

Crack Sealing Equipment

For sealing structural cracks below 1⁄4” wide, core machinery includes routing devices that clean and shape channels, compressors feeding sealant kettles to melt, and prepare emulsified material for application hoses and hand wands manipulated by technicians. Well-sealed cracks prevent further pavement deterioration by minimizing water intrusion through vulnerable fissures prone to expanding into greater structural distresses.

Fog Sealing Equipment

Applying rejuvenating fog seal coats less than 0.1 gallons per square yard requires sophisticated bituminous distributor trucks capable of evenly dispersing the thin, heated emulsion layer across target areas through bar attachments with adjustable nozzles, without atomization. This revitalizes aged asphalt binder and protects surfaces from oxidation damage.

Slurry/Micro Surfacing Devices

Blending coarse aggregates and water with emulsified, polymer-modified asphalt cement binder for overlay placement is achieved via continuous flow mixing units that discharge to mechanical spreader boxes. These machines allow the customization of mixture recipes dispensed for durable, flexible cold application surfacing.

Thin Hot Mix Overlay Equipment

Elevating ride quality through ultrathin lifts necessitates HMA mixing facilities to prepare fresh, smooth asphalt for paver machinery equipped with laser-guided screeds that achieve target mat thickness, before employing rollers to optimize density and compaction levels for strength. This layered resurfacing technique sustainably renews the pavement profile.

Diamond Grinding Machinery

Restoring macro-texture and friction relies on gangs of closely spaced diamond saw blades mounted on a heavy, specialized grinding machine following host pavers to cut precise groove patterns across pavement area, facilitated by vacuum attachments and water spray systems that remove generated slurry.

Achieving Pavement Longevity Through Proactive Asphalt Maintenance

Asphalt pavement systems are intricate networks composed of foundational subgrade soil, aggregate bases, and flexible surface courses bound by viscous bitumen binder mixtures. As core infrastructure assets facilitating transportation across urban and rural landscapes alike, asphalt surfacing integrity affects road quality, vehicle efficiency, and public safety alike.

Yet the repeated loads and weathering effects inevitably degrade the structural bonds and surface quality of aging pavement over their service life cycle. Without intervention, fatigue cracking, rutting, and potholes signal diminishing pavement health. Still, strategic surface treatments applied timeously can sustain functional pavement systems for extended durations.

Classifying Asphalt Rejuvenation Approaches

Infrastructure managers possess an array of asphalt repair methodologies classified within broader rehabilitation frameworks aimed at restoring pavement functionality. Surface-level treatment methods include crack repairs like routing and sealing to mitigate water intrusion along with localized patching interventions. For weathering surfaces, fog seals, slurry seals, and micro-surfacing offer rejuvenating overlays that enhance water resistance and skid qualities.

At more structural levels, mill-and-fill procedures grind away deteriorated surface layers before overlaying thicker hot mix asphalt courses to resurface the pavement profile. Full reconstruction follows when preservation strategies no longer ring viable, fully removing the degraded pavement system to rebuild roadbed layers and apply fresh asphalt.

Yet the costs, resources, and traffic disruptions escalate with reconstruction-focused techniques compared to preventative maintenance preservation efforts. Road owners strive to sustain sufficient surface quality as long as possible via surface renewal options before pursuing deep rehabilitation.

My experienced approach to Pavement Longevity Through Proactive Asphalt Maintenance in US state project locations:

| Project ID | State | Treatment Type | Description | Layer Depth | Existing Condition Requirements | Cost Factor | Service Life Extension |

|---|---|---|---|---|---|---|---|

| CA-1 | California | Crack Sealing | Crack Routing & Sealant Application | Surface | Non-working Cracks < 0.5” | 1x | 2-4 years |

| TX-2 | Texas | Pothole Patching | Square-cut Patch with Fresh HMA | Surface | Potholes, Small Failed Areas | 2x | 1-2 years |

| FL-3 | Florida | Fog Sealing | Thin Rejuvenation Coating | Surface | Oxidation, Raveling, Minor Cracking | 3x | 2-3 years |

| NY-4 | New York | Slurry Sealing | Thin Emulsified Seal Coat | Surface | Minor Cracking, Light Raveling | 5x | 3-5 years |

| IL-5 | Illinois | Microsurfacing | Thin Polymer-modified Mixture Overlay | Surface | Oxidation, Rutting < 0.5″, Light Cracking | 10x | 5-7+ years |

| PA-6 | Pennsylvania | Ultrathin Bonded Wearing Course | HMA Lift < 0.75” | Surface | Minor Rutting, Roughness | 25x | 5-7 years |

| OH-7 | Ohio | Thin HMA Overlay | HMA Lift 0.75-2” | Resurfacing | Moderate Defects, Medium Rutting | 50x | 7-10 years |

| MI-8 | Michigan | Mill & Standard HMA Overlay | Mill 1-2” & Overlay 1.5-3” | Resurfacing | Significant Distress, Deep Rutting | 150x | 10-15 years |

| MN-9 | Minnesota | Mill & Polymer HMA Overlay | Mill 1-2” & Durable Overlay 1.5-3” | Resurfacing | Extensive Damage, Major Rutting | 175x | 15-20+ years |

| WA-10 | Washington | Cold In-Place Recycling | Pulverize & Stabilize Existing Material | Structural Enhancement | Severe Damage, Poor Structural Capacity | 200x | 10-15 years |

| CA-11 | California | Crack Sealing | Crack Routing & Sealant Application | Surface | Non-working Cracks < 0.5” | 1x | 2-4 years |

| TX-12 | Texas | Pothole Patching | Square-cut Patch with Fresh HMA | Surface | Potholes, Small Failed Areas | 2x | 1-2 years |

| FL-13 | Florida | Fog Sealing | Thin Rejuvenation Coating | Surface | Oxidation, Raveling, Minor Cracking | 3x | 2-3 years |

| NY-14 | New York | Slurry Sealing | Thin Emulsified Seal Coat | Surface | Minor Cracking, Light Raveling | 5x | 3-5 years |

| IL-15 | Illinois | Microsurfacing | Thin Polymer-modified Mixture Overlay | Surface | Oxidation, Rutting < 0.5”, Light Cracking | 10x | 5-7+ years |

| PA-16 | Pennsylvania | Ultrathin Bonded Wearing Course | HMA Lift < 0.75” | Surface | Minor Rutting, Roughness | 25x | 5-7 years |

| OH-17 | Ohio | Thin HMA Overlay | HMA Lift 0.75-2” | Resurfacing | Moderate Defects, Medium Rutting | 50x | 7-10 years |

| MI-18 | Michigan | Mill & Standard HMA Overlay | Mill 1-2” & Overlay 1.5-3” | Resurfacing | Significant Distress, Deep Rutting | 150x | 10-15 years |

| MN-19 | Minnesota | Mill & Polymer HMA Overlay | Mill 1-2” & Durable Overlay 1.5-3” | Resurfacing | Extensive Damage, Major Rutting | 175x | 15-20+ years |

| WA-20 | Washington | Cold In-Place Recycling | Pulverize & Stabilize Existing Material | Structural Enhancement | Severe Damage, Poor Structural Capacity | 200x | 10-15 years |

Asphalt Preservation in Practice

“An ounce of preservation is worth a pound of rehabilitation.”

Proactive maintenance philosophies endorse techniques like crack sealing, fog sealing, slurry sealing, and micro surfacing to protect existing pavement integrity rather than allowing extensive failures to trigger deeper repairs.

Timely applications preserve water resistance, surface friction, and structural soundness. Such preventative surface renewal solutions also cost mere fractions upfront compared to extensive road reclamation and complete structural rebuilds.

Micro-Surfacing Application Serving as a minimally disruptive surface maintenance option, micro-surfacing offers a versatile preservation solution for aging asphalt spans facing surface defects like oxidization, pitting, and wearing but still structurally sound at base levels.

With a rapid one-hour return to service after application, micro-surfacing generates minimal traffic delays compared to alternative rehabilitation techniques. The thin polymer-modified cold-mix application also utilizes sustainable construction methods by integrating reclaimed asphalt into fresh pavement mixtures.

The layered application protects against water and UV ray infiltration while restoring skid resistance and pavement coloring with flexible design modifications for unique project conditions. With typical service life extensions of 7-10 years, micro-surfacing renders substantial longevity value for aging pavement due to its non-intrusive nature, durable surface upgrades, and cost-efficient rapid renewal capabilities.

Specialized material terminology holds intrinsic relationships – micro surfacing fits under the surface treatment umbrella which serves under the holistic pavement preservation framework itself, for example. Recognizing the interconnections between material techniques, localized repairs, global renewal strategies, and complete asset rebuilds allows road owners to optimize rehabilitation decisions and construction spending on asset management. Continued progression of material science and repair methodologies promise even longer lifespans in sustainable flexible pavement systems to come.

What are the differences between asphalt repair terminologies: preservation vs rehabilitation vs reconstruction?

As a pavement engineer, I distinguish between preservation techniques applied timely to maintain surface integrity versus more substantial rehabilitation methods that renew deeper layers and full reconstruction that rebuilds the entire pavement structure. Crack sealing and thin overlays preserve assets proactively before major failures, while repairs like mill & fills rehabilitate damaged sections. Reconstruction removes and replaces failed foundations. Prioritizing strategic preservation maximizes taxpayer return on infrastructure investments.

How does micro surfacing compare and contrast to related pavement treatments?

Micro surfacing contrasts from other surface treatments in composition and durability while serving as a preservation-focused alternative to deeper rehabilitation. Unlike basic fog seals, micro surfacing incorporates modified binders and lasts over 5 years. It also contrasts from thin hot mix overlays that cost over 25% more. However, it compares to slurry seals using similar application means with greater longevity and flexibility. Overall, micro surfacing strikes an optimal balance between restoration level and value.

Do all pavement defects require reconstruction?

Not at all – in fact most pavement issues like cracking, raveling and minor rutting can be addressed through affordable preservation techniques like micro surfacing rather than full removal and replacement. Strategically keeping surface deficiencies in check via preventative maintenance investments maximizes the lifespan of the underlying structure before major work becomes necessary – saving over 50% in lifecycle costs.

How does milling contrast from pulverization in terms of scope?

While both involve breaking down the existing pavement, milling partial depths contrasts to full-depth pulverization. Milling removes just 1-3 inches for an overlay while cold in-place recycling pulverizes and remixes the entire structure. Milling also contrasts as a resurfacing measure rather than enhancing structural capacity like stabilization. But both play a role for distressed pavements.

What is the semantic relationship between micro surfacing and asphalt durability?

Micro surfacing – as a protective overlay treatment ‐ has a directly proportional, correlated relationship with asphalt pavement durability – meaning increased micro surfacing quality and durability equates to increased longevity of the underlying asphalt structure. This positive correlation results from enhanced water, weather and wear protection upholding structural integrity.

How do pavement management methods synthesize with preservation scheduling?

Robust pavement management system data on network-wide condition metrics ties directly into optimization models that strategically schedule timely preservation activities over a multi-year horizon. This synthesis of inspection data-driven triggers with future renewal programming allows resource-efficient, long-range planning that maximizes the value of treatments applied at the right point in pavements’ deterioration curve.

What meronyms comprise asphalt emulsion components?

Asphalt emulsion contains smaller constituent ingredients known as meronyms that impart desired properties when blended – including base binder asphalt cement supplied from crude oil refining, water to allow emulsion fluidity, and emulsification agents containing organic colloidal substances that facilitate the dispersion of asphalt particles suspended within the water phase.

How do pavement repairs contrast by level of disruption caused?

Surface applications like fog sealing and micro surfacing feature rapid construction and low traffic disruption given their spraying application and fast return-to-service. In contrast, rehabilitation techniques like mill-and-fill require lane closures for grinding off material, hauling away debris and overlaying – creating significantly higher user delays. Full reconstructions close roads completely due to the extensive base work.

What holonyms exist for the classification of pavement defects?

Local distresses like potholes, raveling, and isolated cracks serve as hyponyms under the holonym categories of more widespread deterioration – namely functional distress types like surface deformation, disintegration, and cracking. Correctly identifying both specific deficiency meronyms and their overarching holonym defect types leads to optimal repair selections.

You may also like to read and calculate:

- Concrete Mix Design Calculator

- Enhanced Quantity Calculator

- Asphalt Millings Calculator

- Calculate Asphalt Millings

- Asphalt Repair Calculator

- Asphalt Quantity Calculator

- Driveway Sealer Calculator

- Asphalt Tonnage Calculator Spanish

- Best Asphalt Pavement

- Crushed Concrete Calculator

- Percent to Decimal Calculator

- Asphalt Square Yards to Tons

- Quantity Cost Tool

- Asphalt Driveway Cost

- Square Yards to Tons

- Asphalt Tonnage Estimator

- ESALs Calculator

- Asphalt Tonnage UK

- Square Meter to Square Foot

- Landscaping Material Calculator

- Asphalt Tonnage to Square Yards

- Particle Size Distribution

- Asphalt Material Calculator

- Asphalt Driveway Cost Calculator

- Mix Design Calculations

- Tonnage to Square Yards

- Asphalt Temperature Calculator

- Calculate Mass of Sand

- Square Feet Cost

- Labor Cost Calculator

- Asphalt Material Calc

- Rectangle Material Area

- Asphalt Dry Weight Calculator

- Gravel and Asphalt Calculator

- Asphalt Wearing Course Density