[area_measurement_calculator]

Accurately Calculate Asphalt Quantities for Your Paving Project with Our All-In-One Asphalt Area Measurement Calculator

If you’re planning an asphalt paving project, determining accurate quantities is one of the most critical steps for success. Even a small miscalculation can lead to significant problems like material shortages, wastage, and cost overruns.

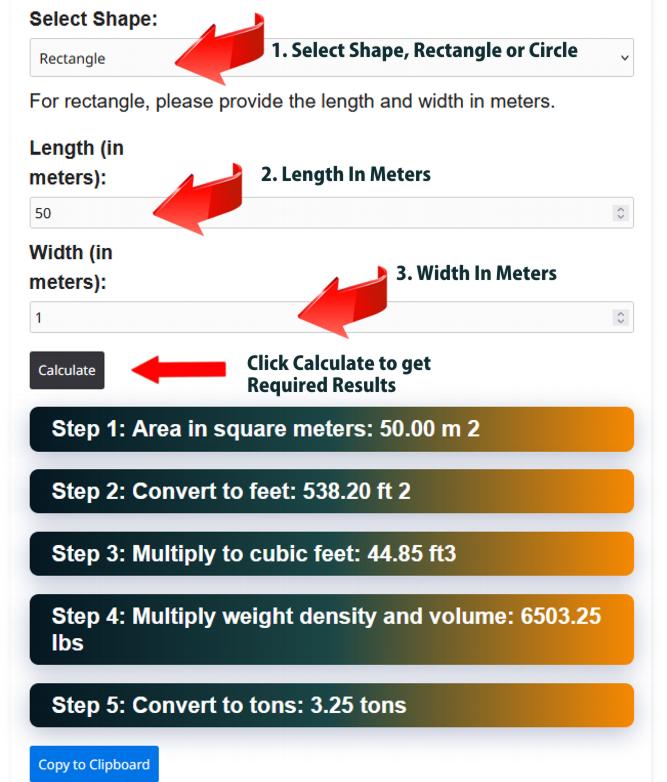

Our easy-to-use Asphalt Area Measurement Calculator takes the guesswork out of estimating asphalt amounts needed for your specific project. In five simple steps, our calculator considers all key variables to provide precise asphalt quantity and tonnage requirements to help your paving job go smoothly.

How to Calculate Asphalt Quantities and Areas

How to Measure the Pavement

| Type of Area | Measuring Guidelines |

|---|---|

| Square | Measure length x width |

| Rectangular | Measure length x width |

| Constant Width Road | Measure the width x length of the road segment |

Coverage of One Ton of Asphalt/Hot Mix

| Thickness (inches) | Coverage (SqM) |

|---|---|

| ½” or 12.7 mm | 95 |

| 1” or 25.4 mm | 48 |

| 2” or 50.8 mm | 24 |

| 4” or 101.6 mm | 12 |

Cost of One Ton of Asphalt/Hot Mix

| Type | Price (per ton) |

|---|---|

| Hotmix | $175.00 + GST |

| Polymer + rubber | $185.00 + GST |

Cost of Asphalt/Hot Mix per Square Meter

| Thickness (inches) | Coverage (SqM) | Cost per SqM (A$) |

|---|---|---|

| ½” or 12.7 mm | 95 | $1.85 + GST |

| 1” or 25.4 mm | 48 | $3.70 + GST |

| 2” or 50.8 mm | 24 | $7.40 + GST |

| 4” or 101.6 mm | 12 | $14.80 + GST |

Why Precisely Measuring Asphalt Quantities Matters

Asphalt density plays a crucial role in converting tons to the area. It’s essential to get this conversion right to avoid wastage and ensure the longevity of the pavement. Ordering the proper amount means:

- No paver downtime from running out of material mid-job

- No leftover asphalt going to waste after the project ends

- The ability to forecast and control paving project budgets

- Efficient planning and coordination of equipment and labor

- Achieving correct coverage and specified thicknesses

Accurate asphalt area and tonnage calculation are the backbones of successful road construction. As technology advances, so do our tools. But the blend of human expertise and technology is what truly paves the way for success. Conversely, incorrectly estimating quantities can lead to:

- Costly shortfalls from inadequate material

- Excess material clogging up the yard and going unused

- Inability to finish paving on schedule

- Uneven coverage and thickness problems

- Frustrating and expensive rework

Getting your measurements right from the start prevents these headaches down the line. Our Asphalt Area Measurement Calculator makes this easy by incorporating all key size metrics and material factors.

How Our Asphalt Area Measurement Calculator Works

The asphalt calculation process involves five simple steps:

Step 1: Measure the Paving Area

- First, determine the area to be paved in square meters.

- For regular shapes like driveways or lots, multiply length x width.

- For odd shapes, divide into smaller rectangles/squares and calculate each section.

Step 2: Convert Area to Square Feet

- Next, convert the area in square meters to square feet.

- Our calculator does this automatically based on the dimensions entered.

Step 3: Calculate Volume in Cubic Feet

- Multiply the area (sq. feet) by the planned asphalt thickness in feet to get volume in cubic feet.

- Example: 300 sq. ft. area x 0.25 ft. (3 inch) thickness = 75 cu. ft. volume

Step 4: Factor in Asphalt Density

- Asphalt weighs around 145 pounds per cubic foot.

- Multiplying cubic feet by 145 gives the total weight in pounds.

- Our calculator performs this calculation automatically.

Step 5: Convert Weight to Tons

- Finally, convert the total asphalt weight to tons.

- 2000 lbs = 1 ton

- Our tool handles conversions to give you the precise tons needed.

It’s as simple as that! Our easy-to-use calculator streamlines the entire quantity estimation process in seconds.

Added Features to Further Refine Your Asphalt Tonnage Calculation

Our upgraded asphalt area calculator incorporates additional options so you can fine-tune the quantity estimate for your specific job:

Factor in Compaction Rate

- Our tool lets you input the expected compaction or density percentage.

- Higher compaction means less asphalt is required.

- This results in an even more accurate material quantity estimate.

Calculate Both Layers for Overlays

- For overlays, calculate the base and top layer tons separately.

- Different thicknesses and mixes can be specified for each layer.

- The calculator sums up the totals for both courses.

Estimate Residual Asphalt in Millings

- When recycling old asphalt millings into the new mix, input the % rap content.

- This accounts for residual asphalt binder in the millings so you don’t overorder.

- Milling content can be factored on a per-layer basis.

Output in Tons or Bags

- Get your material needs estimate in total tons required.

- Or switch to bags calculation mode to order bagged products like patch mix.

With these advanced features, you can dial in an extremely precise asphalt quantity estimate customized for your specific overlay or full-depth project.

Asphalt Area Measurement Calculator Provides the Foundation for Success

Accurately calculating how much asphalt is needed ensures:

- You have exactly enough material to complete the project

- Minimal leftover material that would be wasted

- A smoother paving operation without material shortfalls

- Tighter control over your paving budget and total project cost

- More precise planning of equipment rentals and labor

With a rock-solid quantity estimate, you have peace of mind that your paving job will proceed efficiently with no surprises or headaches caused by incorrect measurements.

Our easy-to-use Asphalt Area Measurement Calculator does the hard work so you have one less thing to worry about. Input your key dimensions and material factors and get the precise tonnage required instantly.

FAQs About Our Asphalt Area Measurement Calculator

How can I estimate the asphalt cost for my driveway project?

Estimating asphalt costs for your driveway project involves calculating the surface area, determining the required thickness, and considering the cost per ton of asphalt. You can use an asphalt calculator for precise figures.

What are the different types of gravel used in driveway construction?

Gravel driveways often utilize various types of gravel, including crushed stone, pea gravel, and crushed rock. The choice of gravel type depends on factors like aesthetics, load-bearing capacity, and local availability.

What’s the average depth for an asphalt driveway?

The average depth for an asphalt driveway typically ranges from 2 to 3 inches. However, this depth can vary depending on factors like local climate, expected traffic, and the quality of the sub-base.

How do I determine the amount of concrete needed for my construction project?

To determine the amount of concrete needed for your project, calculate the volume by multiplying the length, width, and depth of the area you’re pouring concrete into. Then, convert the volume to cubic yards.

What are the best materials to use for a long-lasting roof?

Long-lasting roofing materials include asphalt shingles, metal roofing, clay or concrete tiles, and slate. The choice depends on factors like climate, aesthetics, and budget.

How do I calculate the weight of asphalt for a specific area?

To calculate the weight of asphalt for a specific area, you’ll need to know the asphalt density, surface area, and desired thickness. Use the formula: Weight (tons) = Area (square feet) × Thickness (inches) ÷ 12 (inches per foot) × Density (tons per cubic foot).

What’s the typical cost per square foot for asphalt pavement projects?

The cost per square foot for asphalt pavement projects varies widely, but a rough estimate is usually between $2 to $5 per square foot. The exact cost depends on factors like location, project size, and specific requirements.

How can I repair cracks in my asphalt driveway?

Repairing cracks in an asphalt driveway involves cleaning the crack, applying a filler, and sealing it with asphalt sealer. For larger cracks, it may be necessary to use cold-mix asphalt or consult a professional.

How can I prolong the lifespan of my asphalt driveway?

To prolong the lifespan of your asphalt driveway, routine maintenance is crucial. This includes sealing the surface every 2-3 years, filling cracks promptly, and avoiding heavy vehicle traffic.

What’s the average lifespan of asphalt shingles on a residential roof?

The average lifespan of asphalt shingles on a residential roof is around 20 to 25 years. However, this can vary depending on factors like climate, installation quality, and shingle type.

What is the milling process in road construction?

Milling is the process of removing a layer of asphalt or concrete from the surface to prepare it for resurfacing or other construction. It’s commonly used to correct surface irregularities and improve the road’s condition.

How do I calculate the number of tons of asphalt needed for my paving project?

To calculate the number of tons of asphalt needed, you must know the area to be paved, the desired thickness, and the asphalt density. The formula to use is: Tons = Area (square feet) × Thickness (inches) ÷ 12 (inches per foot) × Density (tons per cubic foot).

What are the different types of asphalt mix materials used in road construction?

Road construction employs various asphalt mix materials, including hot mix asphalt (HMA), warm mix asphalt (WMA), and cold mix asphalt. The choice depends on factors like project specifications and weather conditions.

How can I prevent water from pooling on my asphalt driveway?

To prevent water from pooling on your asphalt driveway, ensure proper slope and drainage. The driveway should be sloped to direct water away from the home and have a suitable drainage system.

What’s the typical cost of milling asphalt for road projects?

The cost of milling asphalt for road projects depends on factors like the area to be milled, the depth of milling, and local pricing. On average, milling costs can range from $0.25 to $0.60 per square foot.

Does the Asphalt Area Calculator work for driveways, roads, and parking lots?

Yes, our calculator can estimate asphalt quantities for any size paving project – driveways, residential roads, municipal streets, highways, lots, courts, etc.

Can I get the estimate in tons or bags?

Our tool can output your asphalt needs in either total tons or the number of bags required. Switch between these units easily.

Does it handle millings and different layers?

Yes, you can factor in existing milling content and specify separate base and wearing course layers to refine your calculations.

What are the different types of asphalt used in road construction?

In road construction, various types of asphalt are employed, including bitumen, asphalt binder, cold mix asphalt, warm mix asphalt, and reclaimed asphalt pavement. Each type serves specific purposes in different construction scenarios.

How is asphalt typically used in paving projects?

Asphalt is commonly used in paving projects to create road surfaces, driveways, and parking lots. It is a versatile material known for its durability and ability to withstand heavy traffic loads.

What are the advantages of using asphalt for road surfaces?

Asphalt offers several advantages for road surfaces, including durability, ease of maintenance, cost-effectiveness, and the ability to be recycled or reclaimed. Its flexibility and resistance to cracking make it a preferred choice for many projects.

How does the density of asphalt affect road construction?

The density of asphalt plays a critical role in road construction as it determines the strength and longevity of the road surface. Proper compaction and density are essential to ensure the asphalt surface can withstand traffic loads and environmental factors.

What are the key considerations when selecting asphalt for a specific project?

When selecting asphalt for a project, factors like the type of traffic, climate conditions, load-bearing requirements, and budget should be considered. The choice of asphalt must align with the project’s specific needs.

Can asphalt be used for roofing applications?

Asphalt is commonly used in roofing applications, typically in the form of asphalt shingles. It provides excellent waterproofing and durability, making it a popular choice for residential and commercial roofs.

How is asphalt related to bituminous waterproofing and roofing felt?

Asphalt plays a key role in bituminous waterproofing, where it forms a waterproof barrier to protect structures from moisture. Roofing felt, often saturated with asphalt, is used in roofing applications to provide additional waterproofing and protection.

What are the environmental considerations when using asphalt in construction?

Environmental concerns in asphalt construction include the use of porous asphalt and reclaimed asphalt pavement to promote sustainability. These practices help reduce water runoff and minimize the environmental impact of construction projects.

What is the role of asphalt in creating porous pavement and its benefits?

Porous asphalt is designed to allow water to pass through, reducing surface runoff and minimizing flooding. It is an environmentally friendly option that aids in stormwater management and maintains groundwater recharge.

How are asphalt and concrete different in terms of construction applications?

Asphalt and concrete serve different purposes in construction. Asphalt is primarily used for road surfaces and pavements, while concrete is commonly employed for building foundations, sidewalks, and structural applications.

What is the significance of coarse aggregates in construction?

Coarse aggregates, often mixed with asphalt or concrete, enhance the structural integrity and load-bearing capacity of construction materials. They are crucial components in creating durable and strong surfaces.

How is asphalt used in road paving and what is its role in creating smooth, safe surfaces?

Asphalt is a fundamental material in road paving, offering a smooth and safe surface for vehicles. Its ability to be compacted and shaped during construction ensures roadways that are comfortable to drive on.

What tools are commonly used in asphalt construction projects?

Asphalt construction projects require various tools, including pavers, rollers, compactors, and asphalt spreaders. These tools are essential for laying and compacting asphalt to achieve a smooth surface.

What is the importance of asphalt in creating flat roofs for buildings?

Asphalt is often used to create flat roofs for buildings due to its waterproofing capabilities. It forms a reliable and durable barrier that prevents water infiltration and protects the building structure.

How can asphalt be utilized in parking lots and what are the cost considerations?

Asphalt is a preferred material for parking lots due to its cost-effectiveness and durability. When planning a parking lot construction project, the cost of asphalt and its installation should be carefully considered to stay within budget.

Start Your Asphalt Paving Project Off Right with Precise Quantities

Now that you know how our all-in-one Asphalt Area Measurement Calculator simplifies estimating exact material requirements for your paving job, why settle for rough guesses? Get the precise asphalt tonnage you need to complete your project smoothly in minutes with our easy tool.

While technology is a boon, the human touch is irreplaceable. I recall a project where the terrain was challenging, but with my expertise and the team’s dedication, we overcame the odds. I am Steve, and I am looking forward to hearing from you. “steve@calculatorasphalt.com”

Visit our website Calculator Asphalt for additional handy paving and construction-related calculators and resources. Our suite of tools provides the vital insight you need for asphalt and concrete projects.